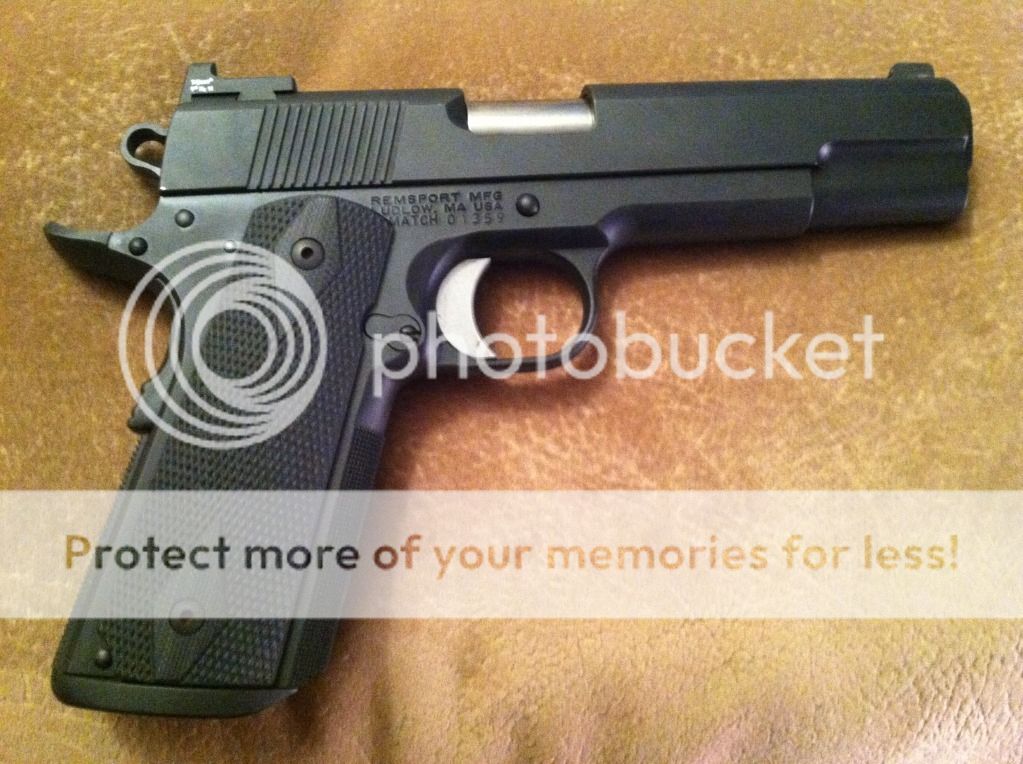

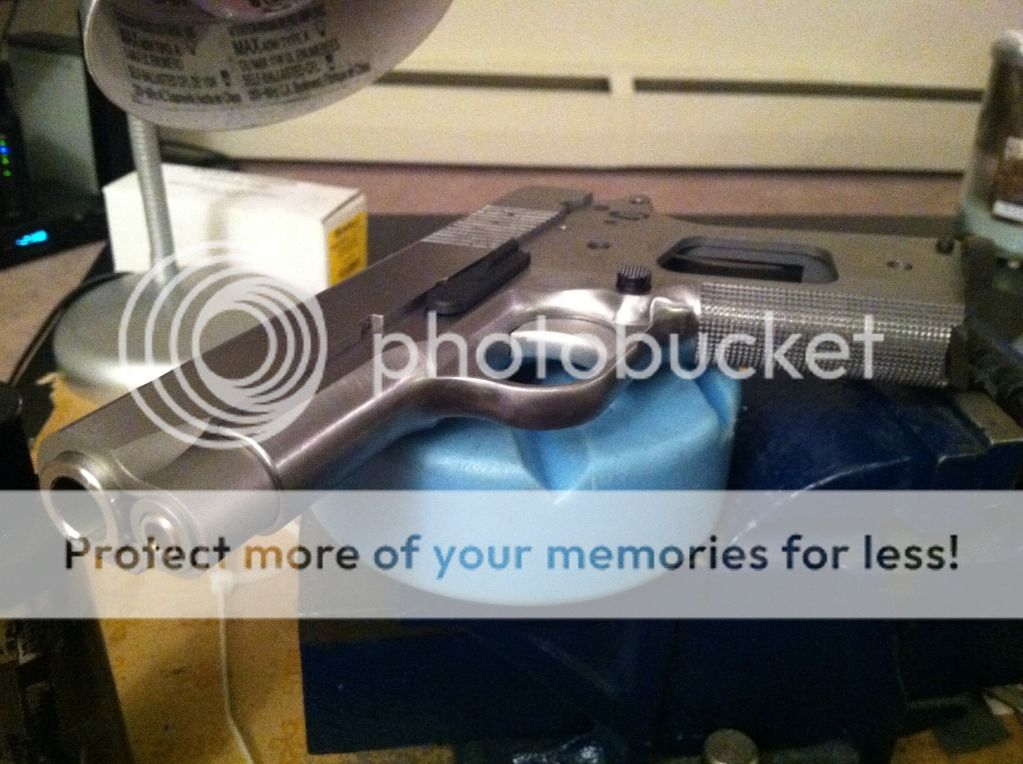

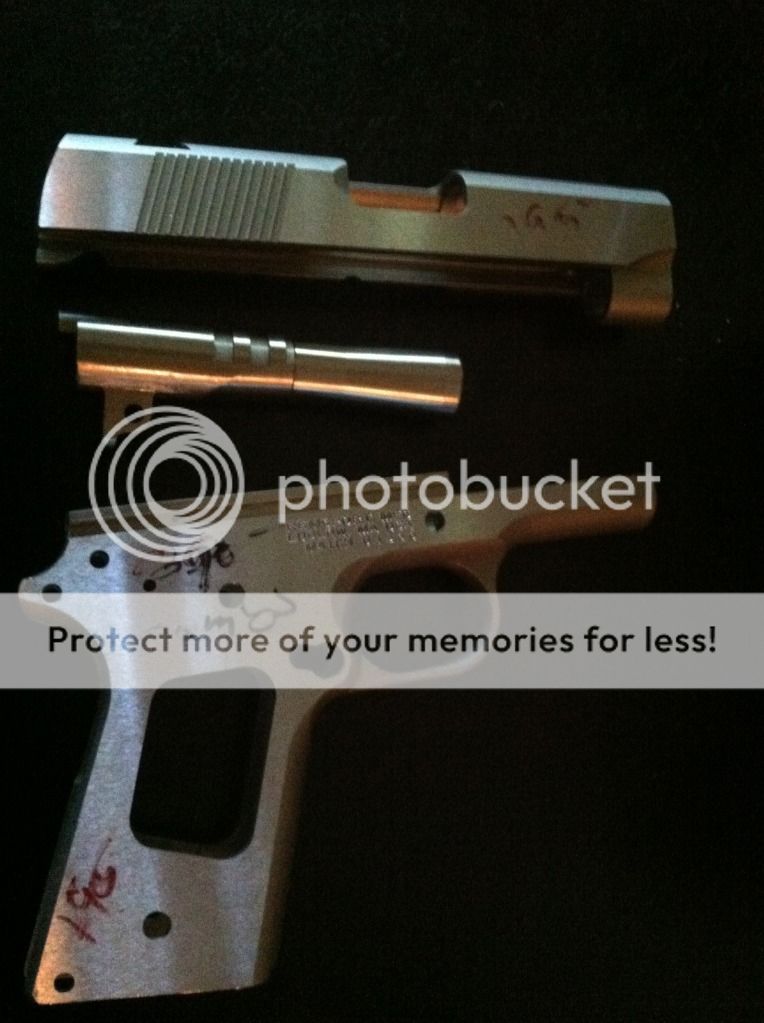

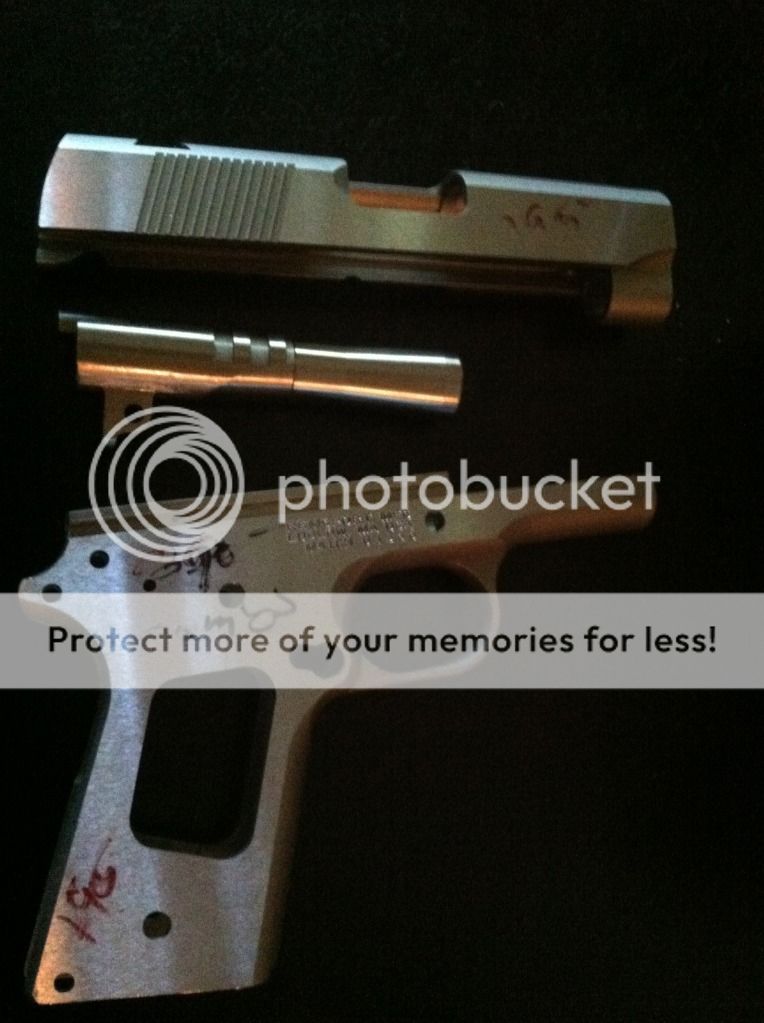

Just started a new Officers build. The slide, frame and barrel are from Remsport. I have to say that their parts seem to be of high quality, please do not turn this thread into a forged not forged or who's better thread!

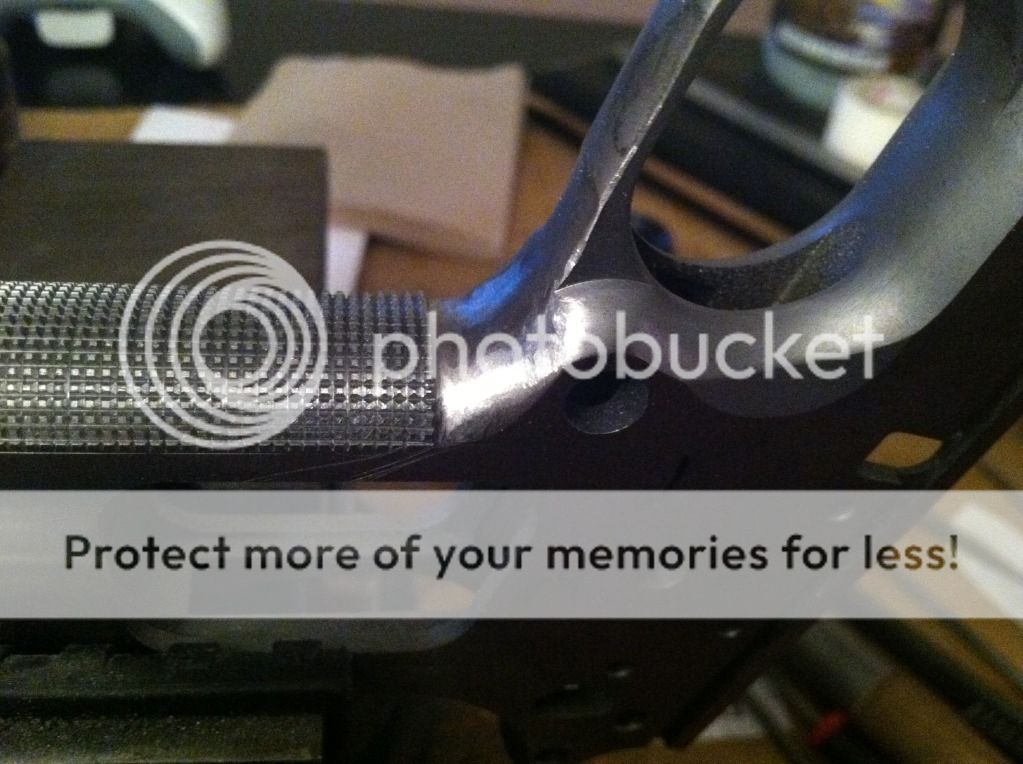

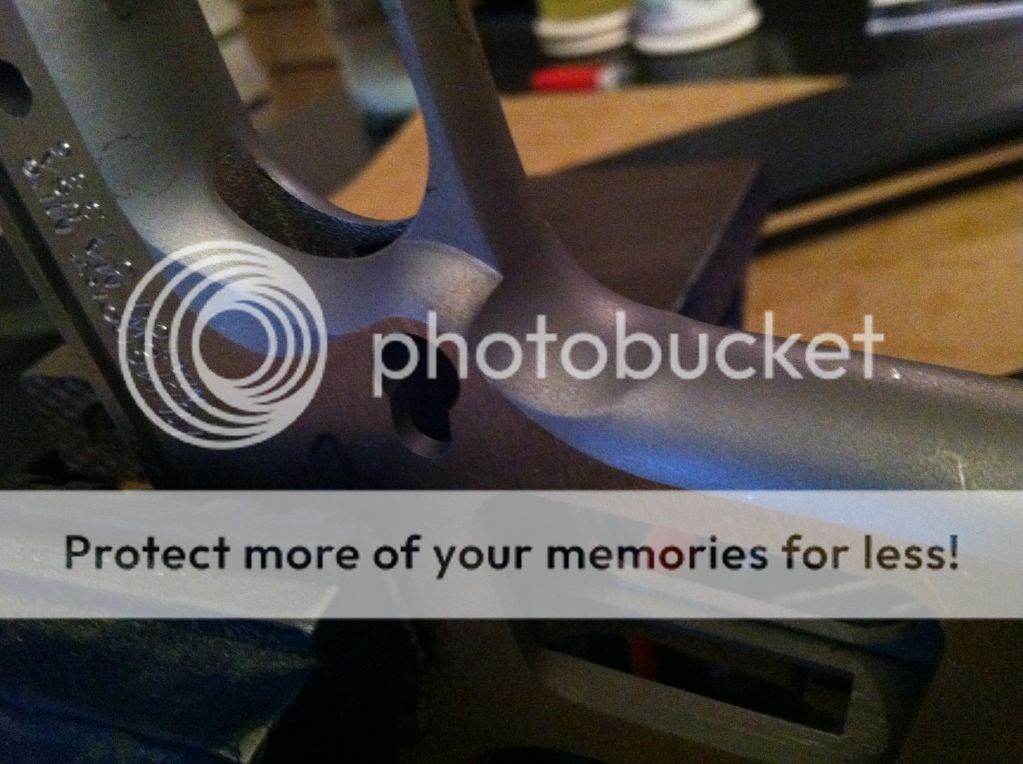

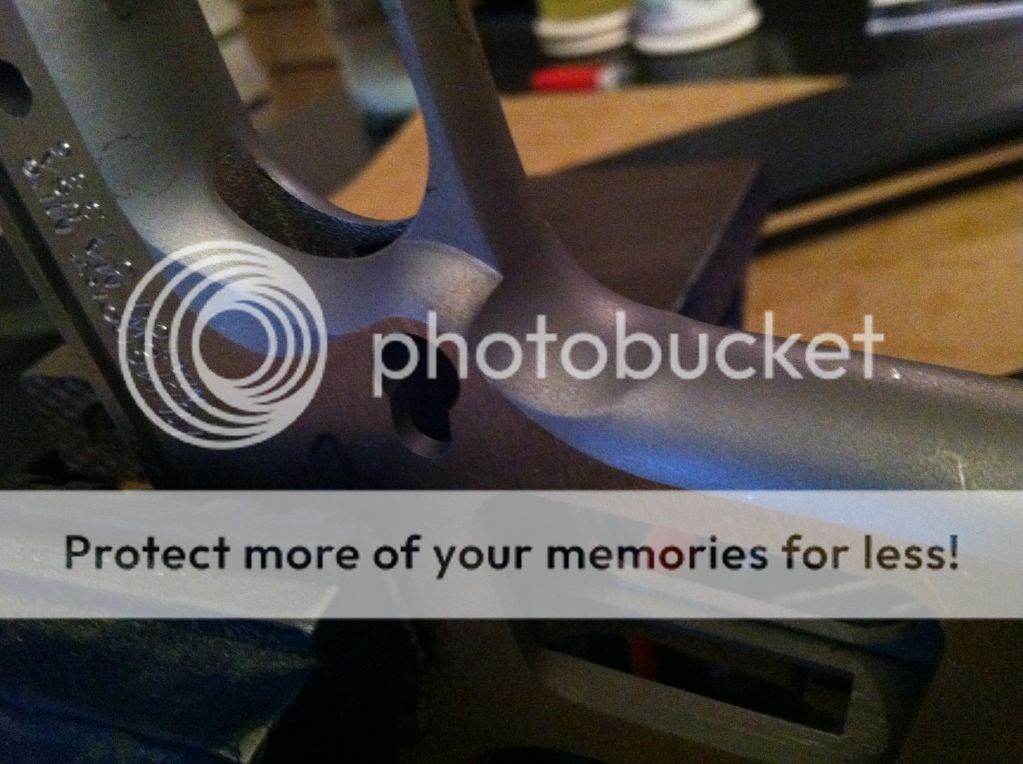

Now if I didn't hack this thing with a rotary tool I wouldn't be having fun!! So this frame comes with a colt style high cut on the front strap and that just won't do so.......

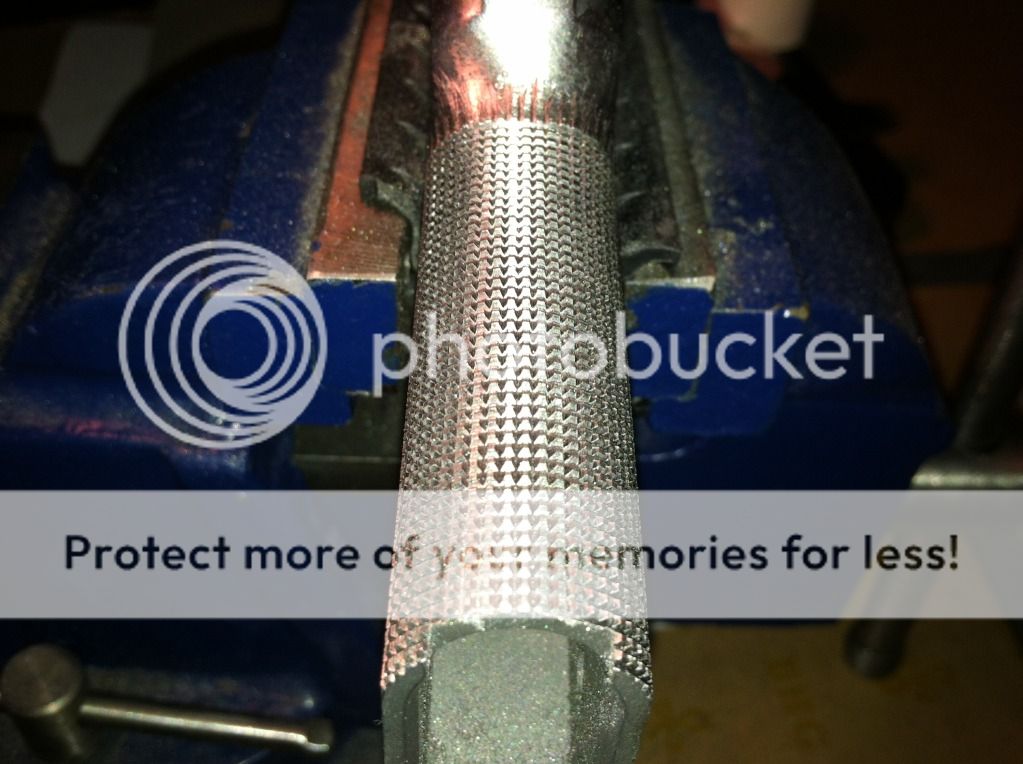

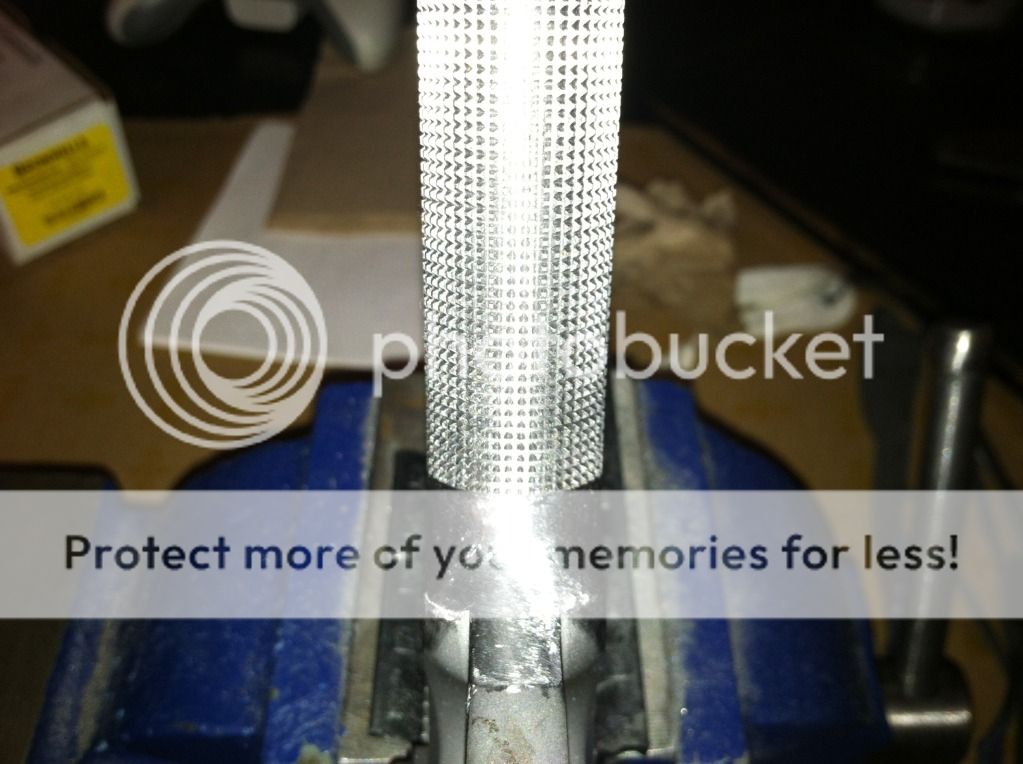

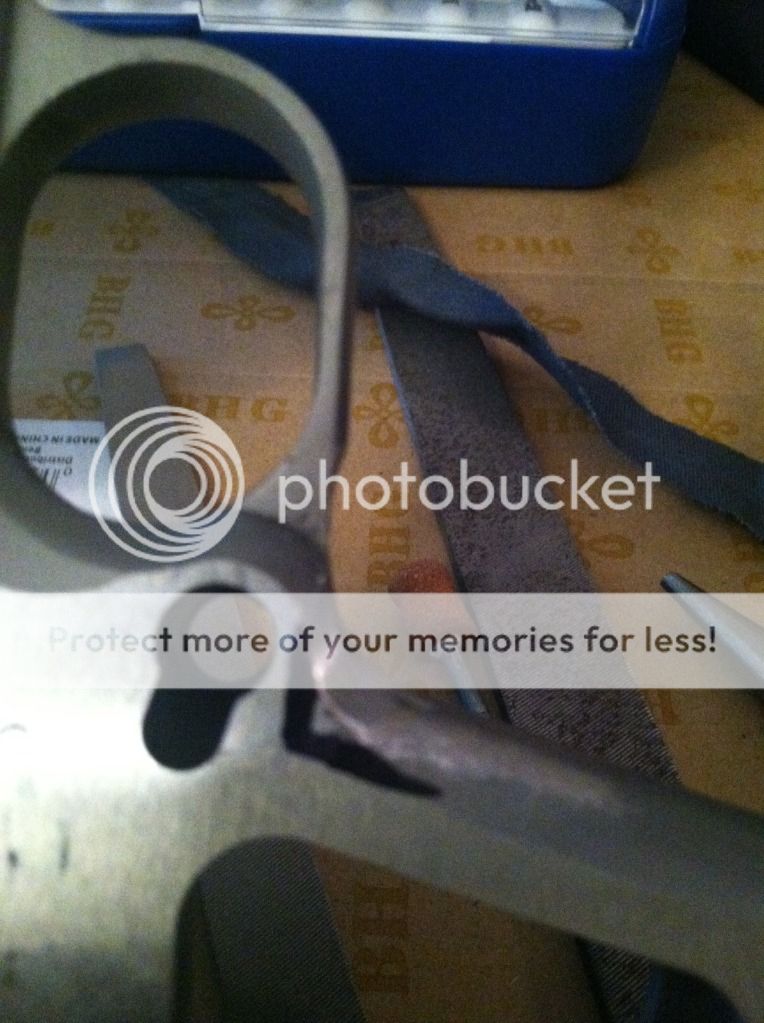

And after I fix the high cut I plan on some hand cut 20 lpi!!!

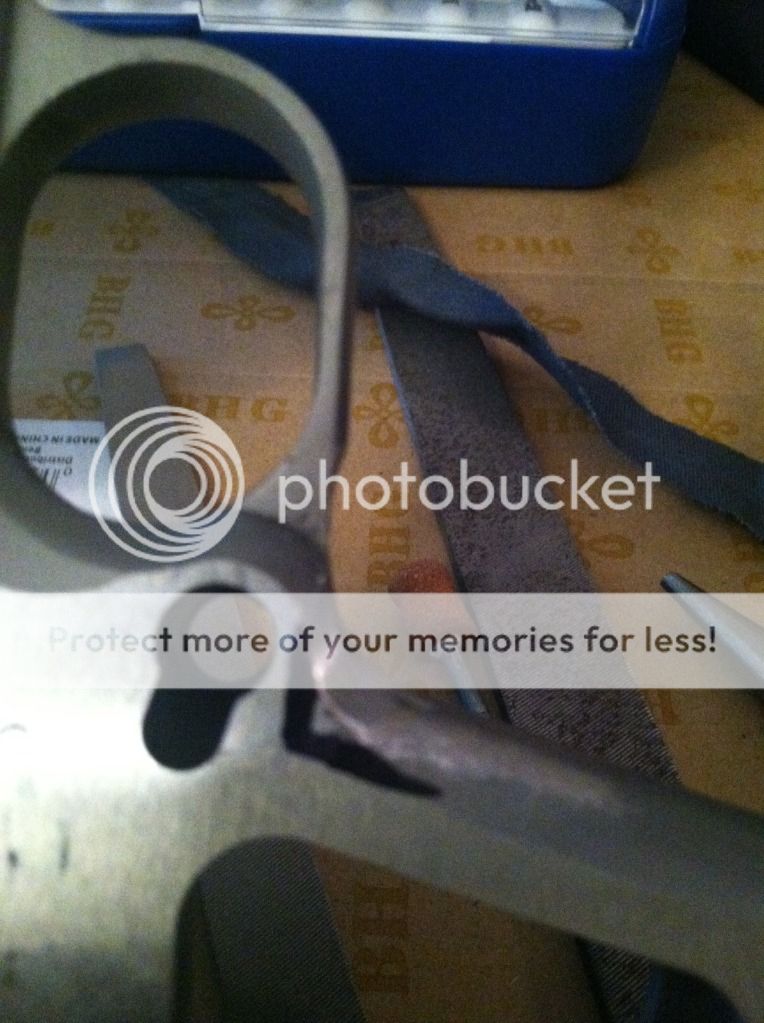

And here I have started to hack at my new frame!!!:hrm:

So I started the 20 lpi cut... It will take some clan up after I'm done but that's when I finish the high cut. Is it me... but right after I start a hand checkering job I ask myself .. Why the hell am I doing this!!!???

It will look great when done but dang its no fun doing it!!!

Now if I didn't hack this thing with a rotary tool I wouldn't be having fun!! So this frame comes with a colt style high cut on the front strap and that just won't do so.......

And after I fix the high cut I plan on some hand cut 20 lpi!!!

And here I have started to hack at my new frame!!!:hrm:

So I started the 20 lpi cut... It will take some clan up after I'm done but that's when I finish the high cut. Is it me... but right after I start a hand checkering job I ask myself .. Why the hell am I doing this!!!???

It will look great when done but dang its no fun doing it!!!

Last edited: