I did some 500 Magnum shooting with EC this past weekend. One of the things I asked him about was shooting gloves.

He let me use his pair of Uncle Mikes (in Large size, which was perfect for my hands) for a few shots. WOW! Big difference handling this gun.

I went looking for a pair for myself, and was saddened to find out that Uncle Mikes has dropped their shooting gloves from their product lineup for 2010. There are still a few pairs floating around out there, but I decided to keep looking. PAST also makes shooting gloves, and at first glance, their gloves seemed to be almost the same as Uncle Mikes (some people suspect that PAST made the gloves for Uncle Mikes)... However, when reading the reviews on Midwest USA, I see that LOTS of people have had problems with seems coming undone and leather splitting. Scratch them off my list.

So, I sent out some emails to my "technical operator" contacts (LEO's with lots of experience with "gear").... almost to the man, they suggested going to GRAINGERS, and trying out some gel palmed "impact" gloves..... I have one (Graingers) about 1/2 hour rom here, and will stop there later in the week. The models I am looking at are:

- Ergodyne Model 900, Grainger number 1EC80

- Valeo Model VI4880LGWWGL, Grainger number 3NJC1

- Condor Model 2XRU7, Grainger number 2XRU7

- Impacto Model AV408L, Grainger number 4HDK7

I'll report back as to which one I bought after trying them on.

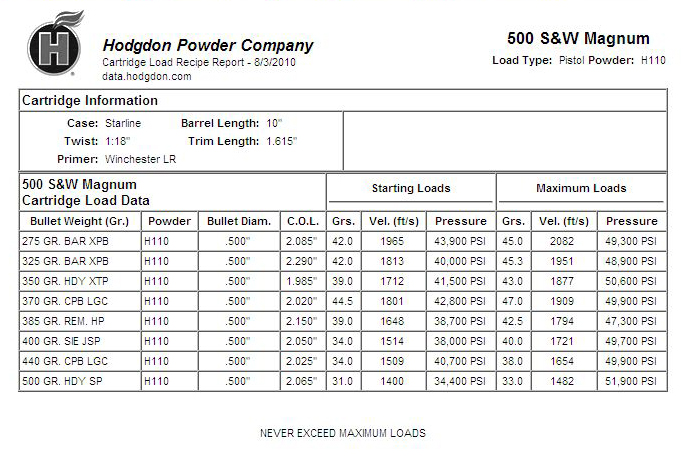

Also, I mentioned to Jim that I had seen the web site for Ballistic Supply, who sells ammo for the S&W 500 magnum. Their site shows a reduced load for this gun with the effective recoil of a 38.

http://www.ballisticsupply.net/Default.aspx?tabid=252105

The trick apparently is to use IMR's "TRAIL BOSS" powder.

In the new 2010 Hodgdon reloading manual, their article says you cannot put enough Trail Boss in a bottleneck case to cause an overcharge problem. They now recommend this method with the powder for using jacketed bullets for reduced loads.

Seat a bullet in brass, mark brass where bottom of bullet is. Pull bullet and fill case with trail boss to the line you have marked for bottom of bullet. Then measure the grains of powder it took to reach mark. This number of grains of Trail Boss you've measured is the 100% load density. Article said you should start your reloads at 70% load density. For example: if a 270 Winchester brass takes 20 grains of trail boss for 100% load density with jacketed bullet you want to use, then multiply 20gr by .70, which gives you the 14 grains, the 70% load density. (20 gr X .70 = 14 grs, the 70% load density) ( 20 gr X .80 = 16gr, the 80 percent load density). Article says to increase charge in 5 grain increments to find trail boss load with best accuracy for jacketed bullet you are using. Optimum accuracy should be between 70 to 100% load density."

"It is impossible to overcharge any cartridge with Trail Boss, simply because it is impossible to get enough into a case to exceed maximum chamber pressures for that cartridge."

Apparently, they do NOT want you to overfill the case. The phrase that they use is: "Don't crush the donuts".... (Trail Boss looks like small donuts.....)

So, using this powder with cast lead bullets should require a call to IMR for confirmation as to use. But, I'm looking forward to getting some quality time in with my 6 3/8" 500 Magnum at low recoil.

BTW, my FreeChex came back as a new version. Having some cycling issues getting the tool to open back up after a bottoming out stroke. I'll almost have to figure out a way to keep the arbor press from going too far. I'm running some copper that I got from Storm Copper. Copper is definitely different than aluminum for these checks.

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)