Bob J

NES Member

Hi Duke,

Gas checks are relatively expensive but much less than a complete purchased cast/GC/Lubed bullet.....![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

Right now I make my own using a Freechex II die set and a Harbor Freight press... Would like to get it in a Freechex III configuration but that might be a while and I know Pat is planning on making a die but that might be a while out as well....

If you decide to buy your gas checks you might want to go through Blammer over on Cast Boolits..... He sets up group buys for gas checks and can save you a fair amount of money....

http://castboolits.gunloads.com/showthread.php?t=86706

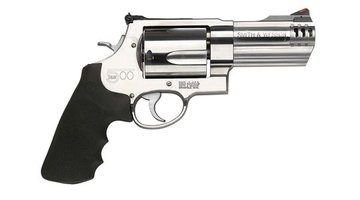

I originally sized to .501 but had some problems with occasional rounds not fitting the cylinder (due to case run out associated with the bullets not seating perpendicular).... After a discussion with Ranger Rick started sizing to .500 (all his S&W bullets are sized to .500) and using a Lyman M die (highly recommended) the problems all disappeared....

HP is 50/50 water dropped (16 BHN) and the SP is straight WW water dropped (22 BHN), both with LLC Carnauba Red lube.... Never had leading in this gun ever.... Am thinking it might be interesting to try some plain range lead with the new 440 grain RFN to see how soft I can go before I start to lead....![Thinking [thinking] [thinking]](/xen/styles/default/xenforo/smilies.vb/010.gif)

Gas checks are relatively expensive but much less than a complete purchased cast/GC/Lubed bullet.....

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

Right now I make my own using a Freechex II die set and a Harbor Freight press... Would like to get it in a Freechex III configuration but that might be a while and I know Pat is planning on making a die but that might be a while out as well....

If you decide to buy your gas checks you might want to go through Blammer over on Cast Boolits..... He sets up group buys for gas checks and can save you a fair amount of money....

http://castboolits.gunloads.com/showthread.php?t=86706

I originally sized to .501 but had some problems with occasional rounds not fitting the cylinder (due to case run out associated with the bullets not seating perpendicular).... After a discussion with Ranger Rick started sizing to .500 (all his S&W bullets are sized to .500) and using a Lyman M die (highly recommended) the problems all disappeared....

HP is 50/50 water dropped (16 BHN) and the SP is straight WW water dropped (22 BHN), both with LLC Carnauba Red lube.... Never had leading in this gun ever.... Am thinking it might be interesting to try some plain range lead with the new 440 grain RFN to see how soft I can go before I start to lead....

![Thinking [thinking] [thinking]](/xen/styles/default/xenforo/smilies.vb/010.gif)

Bob,

E/C commented on Saturday that the gas checks for these are expensive.

Have you made any progress with asking either Pat Marlin or the FreeChex III guy about making one for this size?

In the meantime, where do you get them from?

Also, I understand that you are running these as 50-50 mix. What are you sizing them to?

(This could become the definitive internet discussion on this subject)

Last edited:

![Shocked [shocked] [shocked]](/xen/styles/default/xenforo/smilies.vb/007.gif)

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)