So I’m still at it!

Been collecting scrap and making ingots in the off seasons. Casting and coating in the winters. Batches of wheel weights and range scrap (separately) that I’ve been lucky enough to come across.

I have a few new molds, all in 9mm still. I got the mp handles to a drill press and put a pin in them to keep the handles from sliding off. I will have to post a pic of that sometime.

I have been having a few conversations off the thread that have taught me more about coating and I have not documented every lesson I have learned here yet, but that is my intention: to make posts from time to time to document the lessons I’ve learned and to hear other members comments so I can continue to learn.

This weekends issue is: getting back to coating.

Issues that came up:

Calibrating my PID. It was reading 30 degrees too cool. I need to find the instructions for how to do that on the promelt 2. It is same PID controller that is in a lot of stuff I see online.

Subsequently my first coat didn’t cure on a few batches and I’ve recooked a few times.

I also think I need to add a little acetone because the solutions have been sitting covered at basement temps for a year.

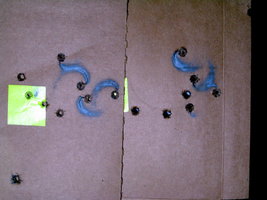

I also think my first coat of 1ml per 1lb was still too heavy (was going to do 1.5ml per 1lb for the 2nd and 3rd coat, if I do a 3rd).

So I’ve passed casting the 10k round mark, and I’m still working on mastering the coating process. I think I had it figured out last winter but I apparently didn’t write it down then, and now I’m back to “America’s Test Kitchen” antics.

I took a section of roofing lead and cut a inch wide strip off and cut a bunch of 1/2 in rectangle out and stamped them with number so I can identify and track my baskets during the coating process.

And my 147gr molds droppings are weighing in at 155gr.

And from now, on my “bitching about my pot dripping” posts will be housed here