Hey Shooters-

Thought Id share my first ground up AR build. They are a lot of fun to build. Hopefully I can get some Varmint with it soon.

Shooters

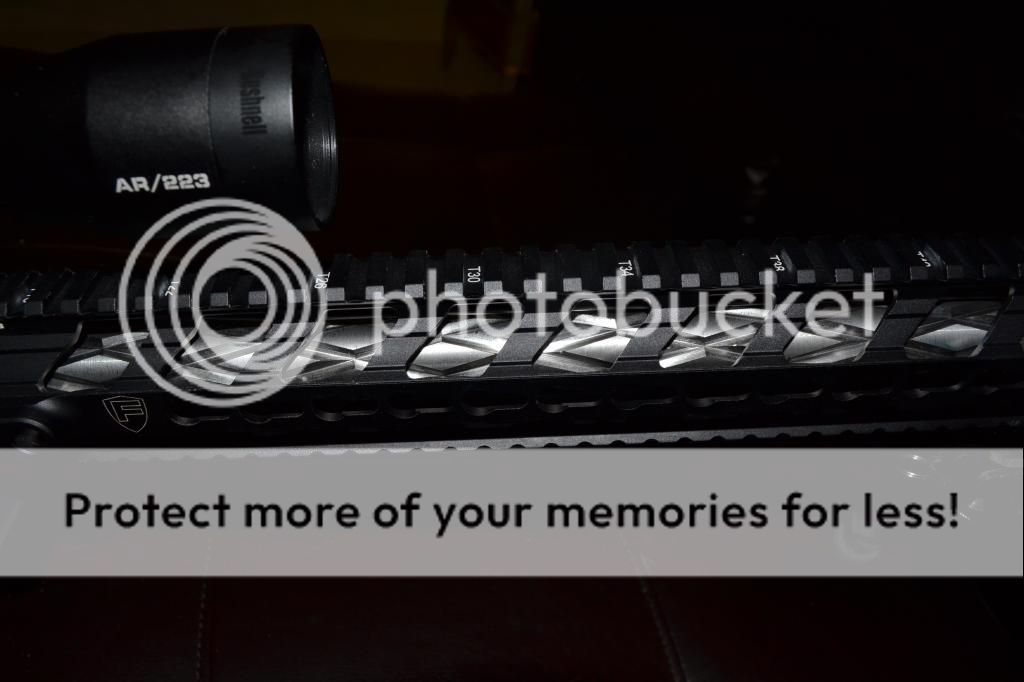

With great pleasure my first AR build. Went for a bench rest/varmint gun. Parts list:

Spikes Lower

PSA lower parts kit

KNS anti-rotation pins

Magpul MOE rifle stock w/ rifle buffer

Mako style pistol grip

WMD upper- NiB coated inner

WMD NiB charging handle

PSA complete NiB BCG

NDZ Army Charging handle flag

NDZ Don't tread on Me forward assist button

NDZ Spartin Dust cover

Extended American Flag take down pins

Red X Arms 20" 1:8 twist Bull barrel with diamond flute

Core 15 barrel nut

14' Fortis REV rail

Burris PEPR mount QD

Bushnell AR 4.5-18 x 40 optic

9"-15" bipod

Thought Id share my first ground up AR build. They are a lot of fun to build. Hopefully I can get some Varmint with it soon.

Shooters

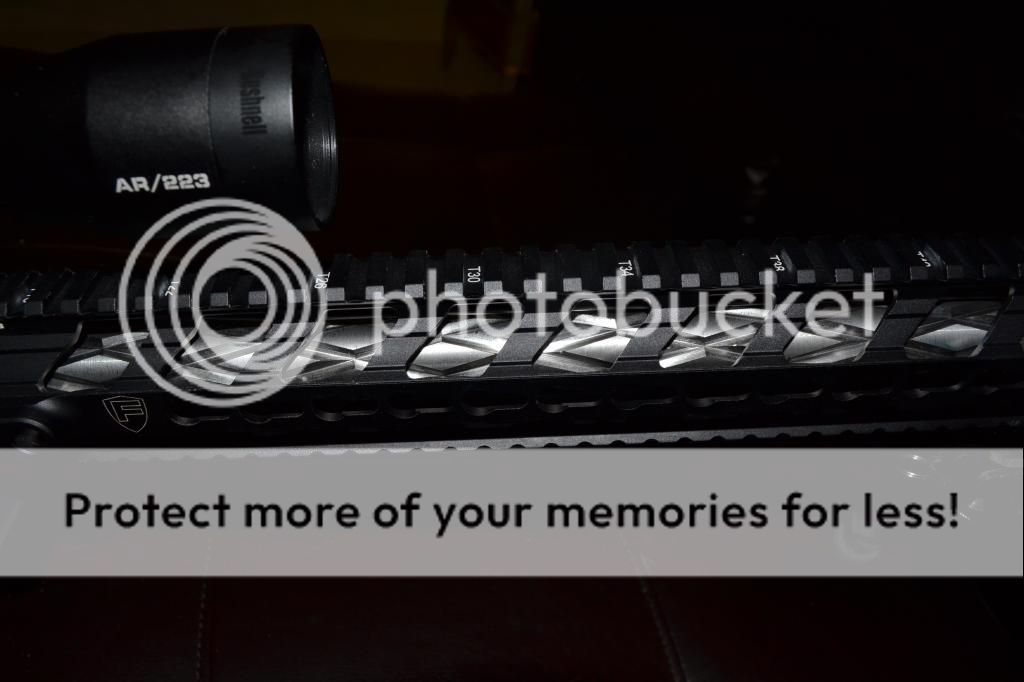

With great pleasure my first AR build. Went for a bench rest/varmint gun. Parts list:

Spikes Lower

PSA lower parts kit

KNS anti-rotation pins

Magpul MOE rifle stock w/ rifle buffer

Mako style pistol grip

WMD upper- NiB coated inner

WMD NiB charging handle

PSA complete NiB BCG

NDZ Army Charging handle flag

NDZ Don't tread on Me forward assist button

NDZ Spartin Dust cover

Extended American Flag take down pins

Red X Arms 20" 1:8 twist Bull barrel with diamond flute

Core 15 barrel nut

14' Fortis REV rail

Burris PEPR mount QD

Bushnell AR 4.5-18 x 40 optic

9"-15" bipod