Hire a good rigger, buy once and cry once. Well worth the money.I'm not willing to run out and buy a heavy duty dolly for this one move, and I'm not willing to move this on my own. The pipes should work, but it would be a pain in the ass. floors not exactly level, and the cast iron frame only makes contact at four points. maybe 4x6" at each point. So the pipes would be a pain.

Would rather just hire someone to come out and get it done.

-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Moving heavy machine?? Metal Lathe

- Thread starter nightpoison

- Start date

- Joined

- Sep 18, 2016

- Messages

- 2,101

- Likes

- 3,953

Just move it inch by inch if you have to. Don't forget that these machines are very top heavy and can get away from you easily.

If I was moving a heavy lathe only 20' or so, I would use a good floor jack with wheels on it on one end, and keep the other end on the floor for stability. Push or pull to new spot. It would be best to have 1 other person to steer the jack by the handle.

If I was moving a heavy lathe only 20' or so, I would use a good floor jack with wheels on it on one end, and keep the other end on the floor for stability. Push or pull to new spot. It would be best to have 1 other person to steer the jack by the handle.

Asaltweapon

NES Member

I’ve moved more machines and tooling racks than I care to think about. Computervision would wash and wax the machine and sheet metal shop floors on first shift. Trouble started when the mucky mucks were in a second floor conference area and a football was seen flying thru the air in the parking lot.

I moved my Bridgeport into my basement by myself after I had a hand getting it off the trailer by a local yard with a Moffit. It was the only help I needed and before I had my tractor or I could have done it all solo.

I moved my Bridgeport into my basement by myself after I had a hand getting it off the trailer by a local yard with a Moffit. It was the only help I needed and before I had my tractor or I could have done it all solo.

Two gantry cranes, Toe Jacks, 2x's, pipes, blocks, scrap wood pieces and my trusty antique 5' nose bar......and.....the Wife

Eastern Rigging Supply - Pry Bars & Nose Bars

www.easternrigging.com

Last edited:

I am reading all these comments and trying to figure out how you get a floor jack under the machine.Just move it inch by inch if you have to. Don't forget that these machines are very top heavy and can get away from you easily.

If I was moving a heavy lathe only 20' or so, I would use a good floor jack with wheels on it on one end, and keep the other end on the floor for stability. Push or pull to new spot. It would be best to have 1 other person to steer the jack by the handle.

I guess a pic would help, but how do you do it?

Depending on garage, there should be places to attach anchors. You can slide machine on bare cement floor or with something under it fairly easily without lifting, if you have heavy straps attached to several anchor points in your garage, basic trig. Hiring riggers is an overkill, a couple of competent guys could easily manage this.

As far as not-leveled floors go, you need to level the lathe in place.

As far as not-leveled floors go, you need to level the lathe in place.

You need riggers to do it safely.

Seriously, to move 1-2 tonne machine on a hard floor 18 feet?

Do they need to have PhD in rigging or Masters would suffice? I can't f***ing believe you guys, I moved many times heavier things, metal, stone, all by myself, it's not rocket science, you do not need a crane or some advanced knowledge, just use your head on top of shoulders. How did humanity ever survived before the ass wiping robot invention?

Seriously, to move 1-2 tonne machine on a hard floor 18 feet?

Do they need to have PhD in rigging or Masters would suffice? I can't f***ing believe you guys, I moved many times heavier things, metal, stone, all by myself, it's not rocket science, you do not need a crane or some advanced knowledge, just use your head on top of shoulders. How did humanity ever survived before the ass wiping robot invention?

So go do it for him stud

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

Obviously he doesn't know what he is doing, otherwise he wouldn't have asked on a forum.

Sometimes, smart people, when doing something that can cause injury because they have no idea what they are doing.. Pay someone to do it for them.

I have a safe I need moved up 2 flights of stairs, why don't you come over with your he-man self and show me how it's done without proper equipment lol

You have experience others don't.Seriously, to move 1-2 tonne machine on a hard floor 18 feet?

Do they need to have PhD in rigging or Masters would suffice? I can't f***ing believe you guys, I moved many times heavier things, metal, stone, all by myself, it's not rocket science, you do not need a crane or some advanced knowledge, just use your head on top of shoulders. How did humanity ever survived before the ass wiping robot invention?

People who don't know wtf they're doing either should recruit someone who does or job it out. Otherwise it can result in property destruction or an unwanted hospital trip, lol. Especially if they have no clue.

We have 2 sauergrapes on the forum now?Some blocks of wood, a pinch bar, Johnson bar, and a pallet jack should do it. With that being said if you don’t have access to that stuff call the closest reputable rigging company. It’s not worth getting hurt or dumping the thing over.

I work for a rigging company on the cape and we do that stuff all the time. You don’t want to pay our travel time up there however.

Mesatchornug

NES Member

So go do it for him stud

Obviously he doesn't know what he is doing, otherwise he wouldn't have asked on a forum.

Sometimes, smart people, when doing something that can cause injury because they have no idea what they are doing.. Pay someone to do it for them.

I have a safe I need moved up 2 flights of stairs, why don't you come over with your he-man self and show me how it's done without proper equipment lol

My reply was to you saying:

You need riggers to do it safely."

and that's just absolutely not the case, let's not over think this, it's a lathe, you don't need to lift it, you can simply drag it if you don't care about the floor. Toppling that thing on its side or dropping it in such a way to harm another human would actually be an awesome accomplishment in the skill of stupidity.

And just like I said, to screw an eye bolt to sill and winch with a cable puller or heavy strap you can get under $100, there is absolutely no need to hire a rigger for it. If you can hire a guy with a head on his shoulders, he doesn't need a certificate or a degree to do it safely. Safety starts with people using their head. If your smart people f*** up so badly, they are not very smart.

Your safe is weak sauce, not even a challenge, but I admit much harder than OP's need.

There are several posts on this.

Depending on the footprint of the machine you will move it in different ways.

Anyone who has been around this type of machinery usually knows how to move it.

As others have said it's not hard to move this type of equipment if you do it smartly. I prefer to move my equipment on a Sunday when no one is around. Including Bridgeport, Monarch ee lathe, Strippit 18/30, 6ft old Wysong Shear, Wales nibbler. All moved with a floor jack, some wood a Gorilla bar and 3 or 4 pieces of round tube or pipe.

But if your not comfortable doing it then just hire a rigger and be done.

Depending on the footprint of the machine you will move it in different ways.

Anyone who has been around this type of machinery usually knows how to move it.

As others have said it's not hard to move this type of equipment if you do it smartly. I prefer to move my equipment on a Sunday when no one is around. Including Bridgeport, Monarch ee lathe, Strippit 18/30, 6ft old Wysong Shear, Wales nibbler. All moved with a floor jack, some wood a Gorilla bar and 3 or 4 pieces of round tube or pipe.

But if your not comfortable doing it then just hire a rigger and be done.

First off no pictures. Second what type of building and no interested 3 weeks out of back surgery. But if you think about it and have a good plan. It's not that difficult with very little tools. For years we moved large equipment with pins wood fence posts Johnson bars cumalongs and chain faults. But as time went on we picked up Hillman rollers winches and other goodies. But we rig a lot of large boilers chillers turbines mill equipment paper mill equipment for temporary shut downs. Have a hydro electric turbine stator to remove out of bear swamp in the fall did the other two years ago it was 650 ton. A couple pictures I think you could do it your self with a little advise

Asaltweapon

NES Member

A 650 ton stator???First off no pictures. Second what type of building and no interested 3 weeks out of back surgery. But if you think about it and have a good plan. It's not that difficult with very little tools. For years we moved large equipment with pins wood fence posts Johnson bars cumalongs and chain faults. But as time went on we picked up Hillman rollers winches and other goodies. But we rig a lot of large boilers chillers turbines mill equipment paper mill equipment for temporary shut downs. Have a hydro electric turbine stator to remove out of bear swamp in the fall did the other two years ago it was 650 ton. A couple pictures I think you could do it your self with a little advise

Holy shit.

cstockwell

NES Member

buy 2 sets of these or similar and use a floor jack to life each corner on and off them. You will get tons of use out of these down the road too. If you need to store briefly or move a car around in tight quarters they are great. For about $50 to 60 for a pair they are well worth it.

Asaltweapon

NES Member

Ive seen a shit load of lathes but never one with wheels.buy 2 sets of these or similar and use a floor jack to life each corner on and off them. You will get tons of use out of these down the road too. If you need to store briefly or move a car around in tight quarters they are great. For about $50 to 60 for a pair they are well worth it.

![Stir the pot [pot] [pot]](/xen/styles/default/xenforo/smilies.vb/037.gif)

So go do it for him stud

Obviously he doesn't know what he is doing, otherwise he wouldn't have asked on a forum.

Sometimes, smart people, when doing something that can cause injury because they have no idea what they are doing.. Pay someone to do it for them.

I have a safe I need moved up 2 flights of stairs, why don't you come over with your he-man self and show me how it's done without proper equipment lol

I helped another member here move a big f***ing safe once, but honestly he is built like the incredible hulk and he had a good idea of what he had to do, plus we had an appliance dolly to do it with, too. I just was there really to act as a guide/spotter and to take some of the load off when we were going through difficult spots. It also helped that he took the door off.

If it was me by myself? I'd either have a party with guys I trusted to help move it, or get a safe mover to do it.

- Joined

- Apr 23, 2011

- Messages

- 1,291

- Likes

- 1,288

Do you need it delivered to your house? Regular towing companies can flat bed it. We've had machines brought to work that way.

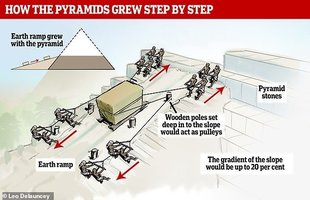

As others have said 1/2" pipes and some pry bars can do wonders without personal injury.

As others have said 1/2" pipes and some pry bars can do wonders without personal injury.

Your wifes back musta been sore.... ![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)

nightpoison

NES Member

Ok guys, so here is some more information.

Its in a basement, its an old cast iron lathe. I've posted a video on Youtube. just click this link >>>> LINK <<<<< to view what the lathe looks like and how far I'm moving it.

I'm currently cleaning the lathe up right now. Removing what I can to lighten it up. Getting everything out from underneath it. Get it ready to move.

As you can see from the the video, its not going to be moving far at all. I'm putting it out of the way as the lathe hasn't run in years if not decades. I'm not much of a metal worker, it was my wifes grandfathers lathe. If I need to work with some metal, I just use the machine shop at work. Eventually, I do plan on getting this up and running, but not just yet. I need some room for my own projects so its being moved to a new location as this is sitting dead center of where I would like to set up my wood lathe and Jointer.

I appreciate the confidence that a number of you have in moving it yourself. I've been considering it, making the attempt. I can rent machine rollers from sunbelt for $35 for the day. I have a bottle jack rated at 3-4 tons so I can get it lifted up. I have my concerns of using a bottle jack directly on the cast iron cross beam to lift it up. Might rent a toe jack and crow bar up one leg to get the two jack on the other side, that brings me up to $60. So depending how much a rigger will charge.

Its in a basement, its an old cast iron lathe. I've posted a video on Youtube. just click this link >>>> LINK <<<<< to view what the lathe looks like and how far I'm moving it.

I'm currently cleaning the lathe up right now. Removing what I can to lighten it up. Getting everything out from underneath it. Get it ready to move.

As you can see from the the video, its not going to be moving far at all. I'm putting it out of the way as the lathe hasn't run in years if not decades. I'm not much of a metal worker, it was my wifes grandfathers lathe. If I need to work with some metal, I just use the machine shop at work. Eventually, I do plan on getting this up and running, but not just yet. I need some room for my own projects so its being moved to a new location as this is sitting dead center of where I would like to set up my wood lathe and Jointer.

I appreciate the confidence that a number of you have in moving it yourself. I've been considering it, making the attempt. I can rent machine rollers from sunbelt for $35 for the day. I have a bottle jack rated at 3-4 tons so I can get it lifted up. I have my concerns of using a bottle jack directly on the cast iron cross beam to lift it up. Might rent a toe jack and crow bar up one leg to get the two jack on the other side, that brings me up to $60. So depending how much a rigger will charge.

Share:

Similar threads

- Replies

- 9

- Views

- 347

- Replies

- 25

- Views

- 449

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)