I think this may have been mentioned somewhere within the guts of some thread. However, worth its own post since it works so well. Here's the drill and tap kit that works with the Hornady OAL gauges that require a prepared case:

https://www.amazon.com/gp/product/B0195UFBUY/ref=oh_aui_detailpage_o09_s00?ie=UTF8&psc=1

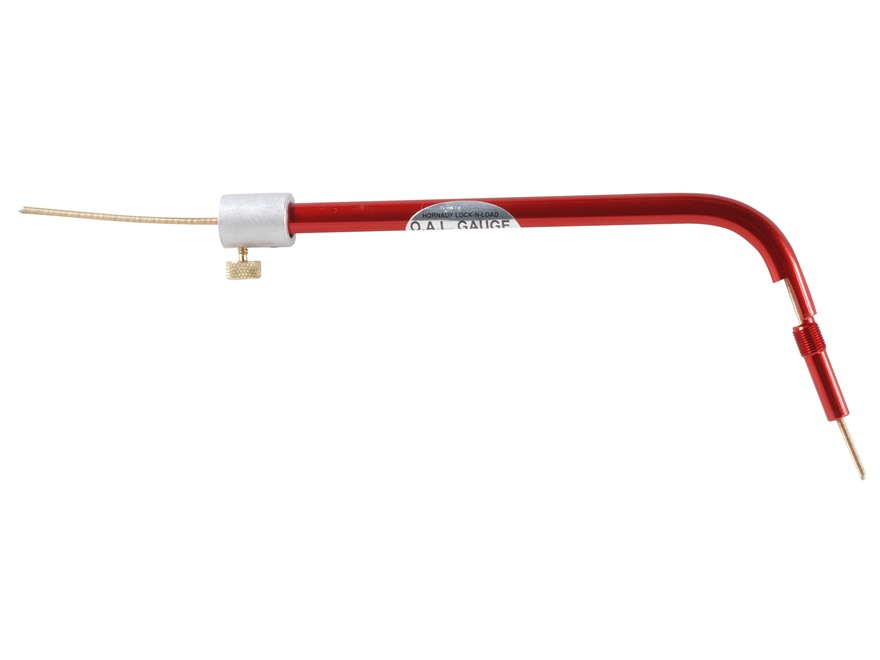

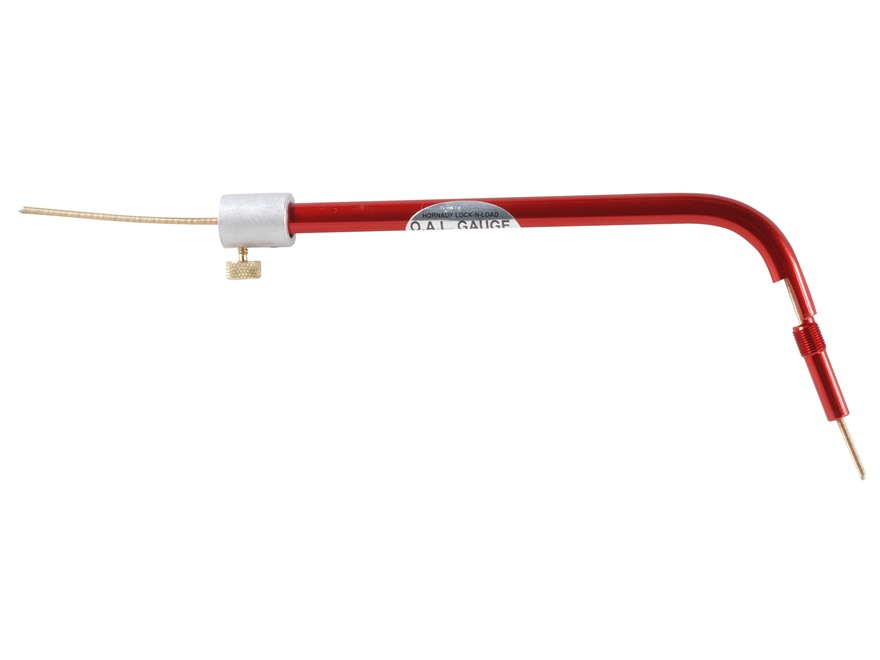

For reference, here's the OAL gauge that I use:

There's a straight one as well, but the curved version is necessary for semi's and works fine for bolt guns too. I've used this tool to develop several great shooting loads for various match rifles and my XP-100 pistols.

This drill and tap kit worked great to make prepared cases for some calibers like 7.5 Swiss, 7.62X54R, etc. and it works like a charm. Works great for the odd calibers and/or to save the trouble of ordering. Make two prepared cases and the drill and tap kit as pretty much paid for itself.

If you have your own workshop w/ lots of drills and taps, for reference the specs are

5/16" - 36 HSS Right hand Thread Tap, requires a 7.3mm Drill bit

https://www.amazon.com/gp/product/B0195UFBUY/ref=oh_aui_detailpage_o09_s00?ie=UTF8&psc=1

For reference, here's the OAL gauge that I use:

There's a straight one as well, but the curved version is necessary for semi's and works fine for bolt guns too. I've used this tool to develop several great shooting loads for various match rifles and my XP-100 pistols.

This drill and tap kit worked great to make prepared cases for some calibers like 7.5 Swiss, 7.62X54R, etc. and it works like a charm. Works great for the odd calibers and/or to save the trouble of ordering. Make two prepared cases and the drill and tap kit as pretty much paid for itself.

If you have your own workshop w/ lots of drills and taps, for reference the specs are

5/16" - 36 HSS Right hand Thread Tap, requires a 7.3mm Drill bit