SJan

NES Member

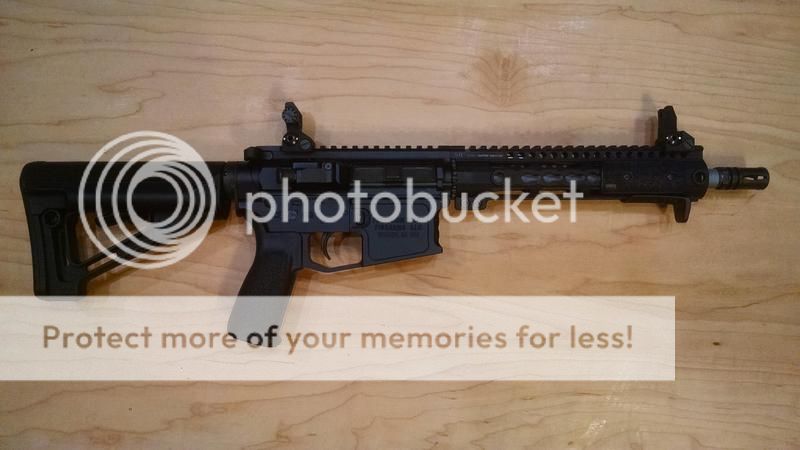

Here is my setup, I just assembled it 2 days ago.

Precision Point receivers

Johnny's secret BCG. (It appears to be quality in every way, just dont know who made it. The bolt is marked MPI, full auto carrier, extractor has o-ring, gas key is tight and properly staked)

Rainer match barrel

BCM gas block, properly aligned with gas port

Midwest rail

Spikes T2 buffer

The buffer tube and spring are from Joe Bob outfitters. It was a package that included the end plate, nut, and a standard buffer. The tube is "mil-spec" but actually measures 1.130-1.132 along its length (should be 1.148) I noticed this and measured it when my stock fit was loose, even with the friction lock engaged, it has slop. While shooting my whiskers caught between the stock and tube... This makes me doubt the quality of the spring as well. Before firing I went ahead and ordered a name brand buffer tube and spring.

I test fired today. I used some of the following ammo:

Federal XM855

Federal XM193

American Eagle 223

these all functioned 100% all fed, fired, ejected, and locked back on empty mag.

I also fired some:

PMC 223

Aguila 223

These had some issues. Sometimes would not lock back on empty mag. Sometimes would not feed next round at all, bolt would close on empty chamber. Sometimes would partially feed next round but not even clear the feed lips.

It was obvious the weaker 223 did not fully cycle this gun, or created an under-gassed situation. I was stupid in not bringing another rifle with me today so I could not try a different bolt. All my other rifles use the same T2 buffer without problem, with all ammo.

The only other buffer I have is the questionable quality standard carbine buffer from the Joe Bob kit, and a Palmetto Armory standard carbine buffer. I had neither with me today.

In my research, 10.5" ARs can be finicky. Buffer weight recommendations often are followed with "YMMV" or "Depending on ammo used"

Should I be satisfied with running fine on quality 5.56 or hotter 223 ammo? Maybe... But I like to know my stuff runs on any ammo.

Next time out I will have a proper buffer tube, spring, and a lighter buffer to try.

Those of you with an AR SBR, what recoil system combination do you run? How does it run on various ammo?

Here is a photo of rifle, because its sexy

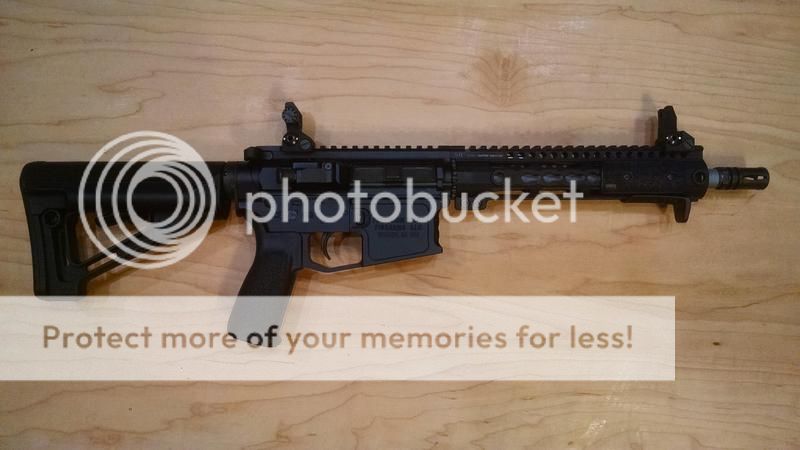

Precision Point receivers

Johnny's secret BCG. (It appears to be quality in every way, just dont know who made it. The bolt is marked MPI, full auto carrier, extractor has o-ring, gas key is tight and properly staked)

Rainer match barrel

BCM gas block, properly aligned with gas port

Midwest rail

Spikes T2 buffer

The buffer tube and spring are from Joe Bob outfitters. It was a package that included the end plate, nut, and a standard buffer. The tube is "mil-spec" but actually measures 1.130-1.132 along its length (should be 1.148) I noticed this and measured it when my stock fit was loose, even with the friction lock engaged, it has slop. While shooting my whiskers caught between the stock and tube... This makes me doubt the quality of the spring as well. Before firing I went ahead and ordered a name brand buffer tube and spring.

I test fired today. I used some of the following ammo:

Federal XM855

Federal XM193

American Eagle 223

these all functioned 100% all fed, fired, ejected, and locked back on empty mag.

I also fired some:

PMC 223

Aguila 223

These had some issues. Sometimes would not lock back on empty mag. Sometimes would not feed next round at all, bolt would close on empty chamber. Sometimes would partially feed next round but not even clear the feed lips.

It was obvious the weaker 223 did not fully cycle this gun, or created an under-gassed situation. I was stupid in not bringing another rifle with me today so I could not try a different bolt. All my other rifles use the same T2 buffer without problem, with all ammo.

The only other buffer I have is the questionable quality standard carbine buffer from the Joe Bob kit, and a Palmetto Armory standard carbine buffer. I had neither with me today.

In my research, 10.5" ARs can be finicky. Buffer weight recommendations often are followed with "YMMV" or "Depending on ammo used"

Should I be satisfied with running fine on quality 5.56 or hotter 223 ammo? Maybe... But I like to know my stuff runs on any ammo.

Next time out I will have a proper buffer tube, spring, and a lighter buffer to try.

Those of you with an AR SBR, what recoil system combination do you run? How does it run on various ammo?

Here is a photo of rifle, because its sexy

Last edited:

![Cheers [cheers] [cheers]](/xen/styles/default/xenforo/smilies.vb/018.gif)