IANAL, but all activities described herein are 100% legal in accordance with both Federal and state laws. If this shocks or disturbs you, please move to any one of the already existing communist shitholes ... or/and Kalifornia. You deserve neither liberty nor security.

I want to give a special thanks to Dark Lord Marsha Cloacaly and the Soviet Rupublic of mAssucktaxachussetts (with fake "Indian" Lizzy on its seal) for making it all possible. Without you, I'd just buy a gen4 Glock.

"Rifles do have a place in the survivalist’s arsenal, and a very important one. But you have to understand that 90% of the time, the handgun will be the weapon you have available when you need one."

Thoughts On Urban Survival by Ferfal

Why Glock ?

History of Glock

How Glocks work

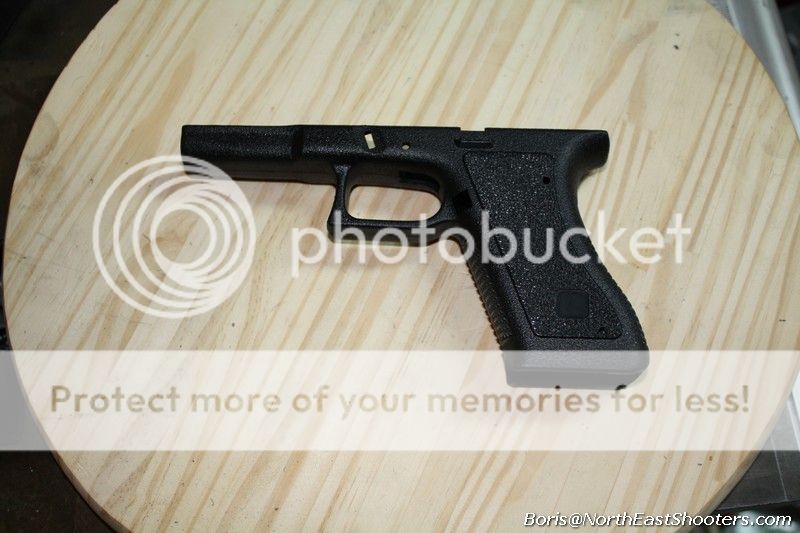

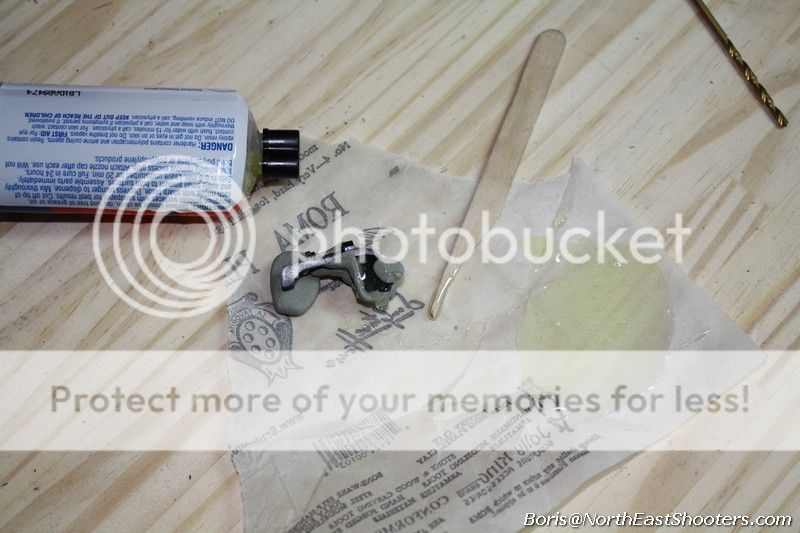

Building your Glock

- Fore-piece, steps F 1 - 3

- Aft section, steps A 1 - 3

- Mid section, steps M 1 - 3

- Joing, steps J 1 - 7

Finishing up

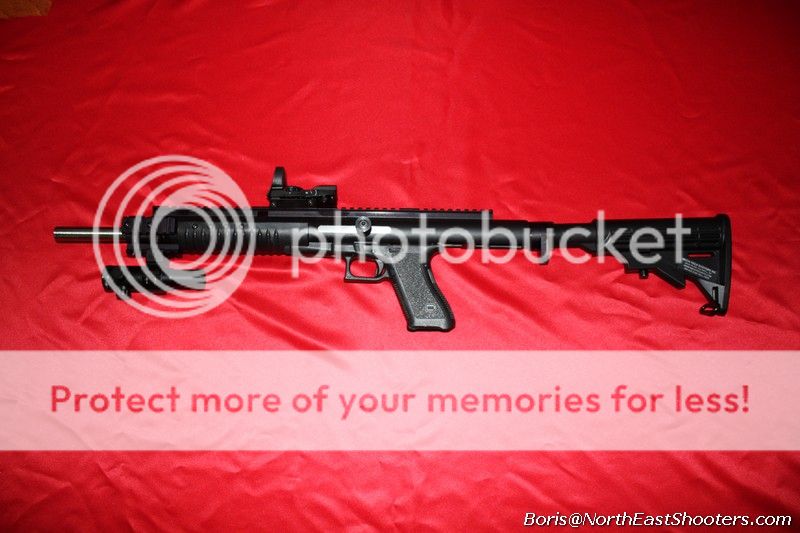

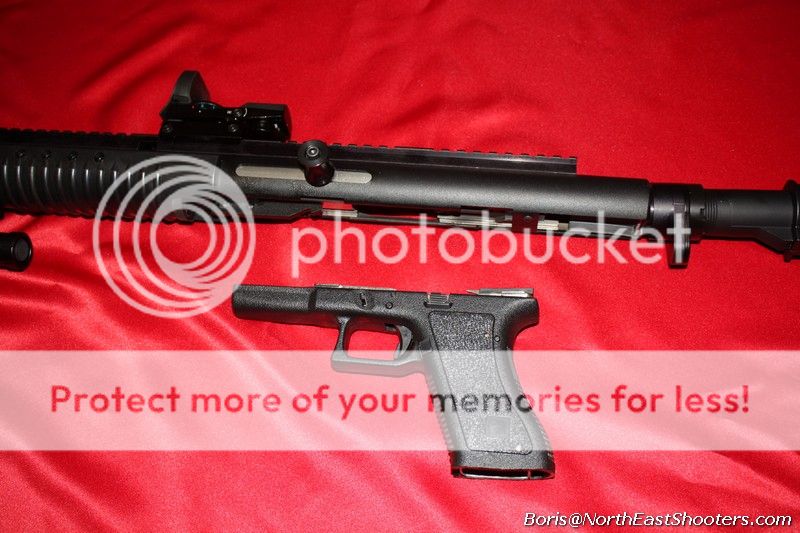

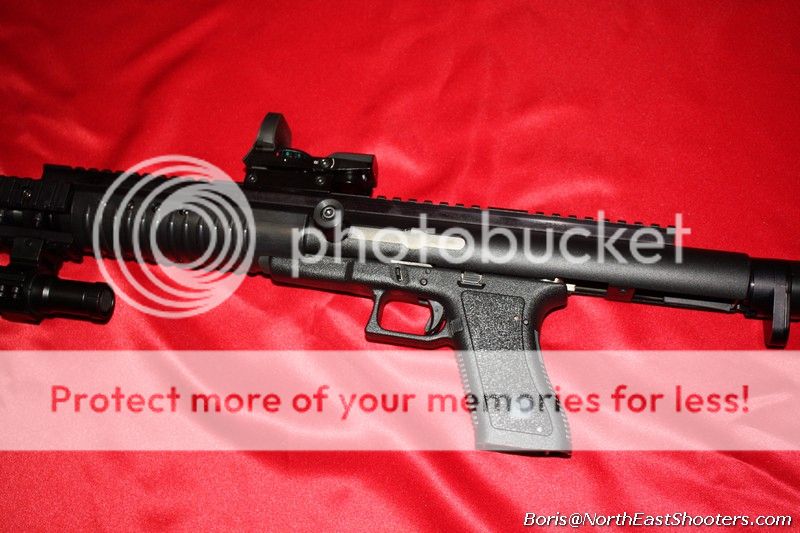

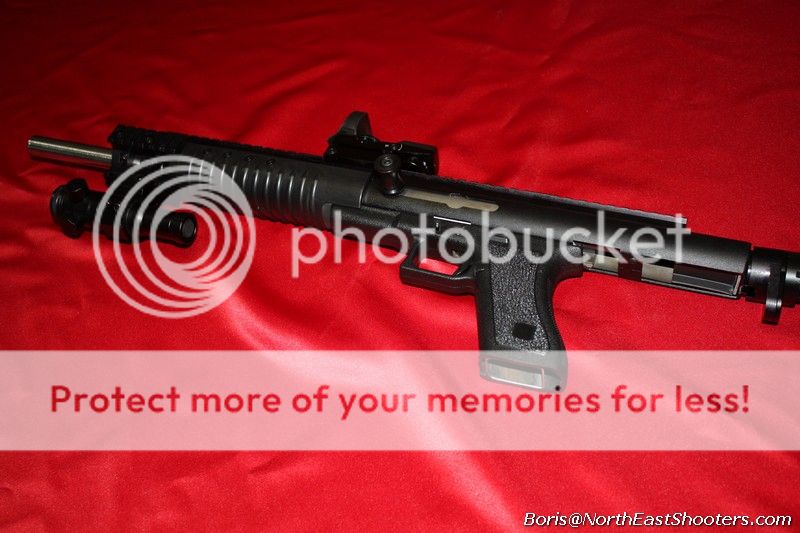

- Mech-Tech upper for your Iron Glock frame

Common Issues and Problems

Vids

List of updates

Why Glock?

Since the dawn of Man, at any time, in any nation, people who bear arms freely without infringements were called FREE MEN. Since the dawn of Man, at any time, in any nation, people who were restricted or banned from bearing arms were called SLAVES or by any other name.

I started to look for a BIY pistol for the time when zombies are not quite roaming the streets yet, but currency already has little value and we have a bunch of crooks running .gov. In other words, cheap, realiable pistol capable of variety of calibers with parts that could be found easily and could interchange. ... also it can't be made out of aluminum (like a lawn chair or AR)

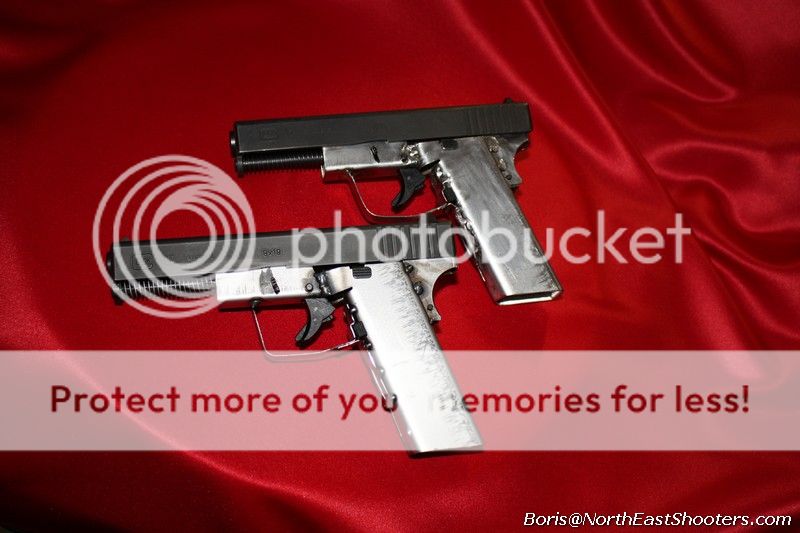

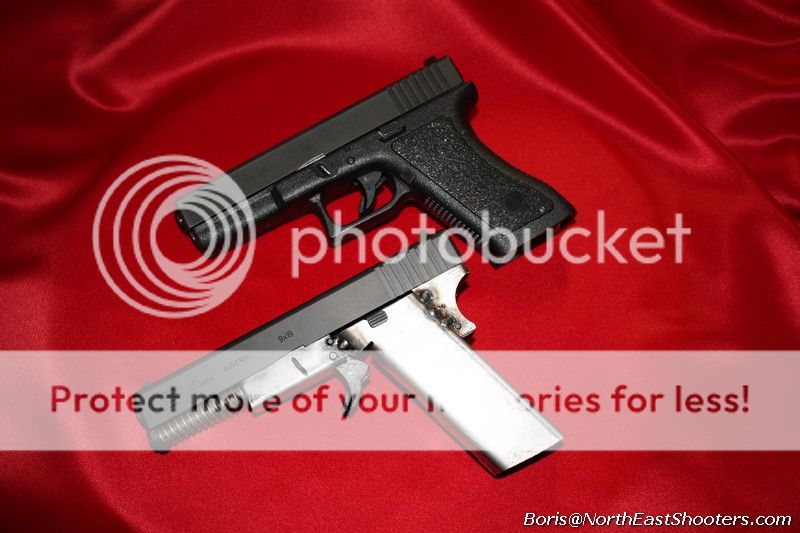

My choice fell on Glocks, the plastic AKs of the pistol cosmos. Glock is the opposite of any typical German gun: simple, loose tolerances making it reliable by even Russian standards, most parts interchange between models and it sucks to shoot. Glocks have many advantages. There are so many of them everywhere that I often check my Krapfen Strudel for Glock parts after I take my morning dump. Several aftermarket companies work day and night making a whole bunch more. Hi cap mags are fairly cheap and very common, but the best part is that having one frame you can switch the slide in a few seconds and shoot 22lr, 9mm, 40 or 357.

If you use terms for pseudo-firearms, ... like ARs, Glock has an upper or the slide that could be changed quickly, like 2 sec quickly without breaking any aluminum hinges (aluminum like in a lawnchair). This upper-slide comes in variety of calibers. The "lower" frame is a piece of plastic that grips Glock's LPK. Amazingly as always, only the plastic frame is considered to be the firearm. LPK that is FCG and few other random bits are typically $75 and are not regulated. Slides are not regulated either and can go anywhere from around $250 and up. With mAss Glock prices for gen 4s sailing north of $800, this is a very attractive option.

four calibers

one "glock" to shoot them all

... Das Eiserne Glock!

History of Glock

Gaston Glock started his career designing curtain rods. He stamped this fruity shit on a Russian stamping press that supposably was left by Kalashnikov himself when he was kicking ass on his tour through Europe. Over the years, vodka vapors used in lubrication and the sheer Awesome radiating from the press kept accumulating until it reached critical mass and made Gaston marry huge boobs with a chick that were less than half of Gaston's age and then pay a ton of money to design Glock17. G17 combined two awesome concepts: St. JMB's locking barrel design and Kalashnkov's principles of manufacturing cheap, reliable guns. It's like US made vodka: it tastes good while making you a filthy capitalist pig in the process.

While Glock has become an iconic firearm, Gaston's skill as an engineer are probably on par with St. JMB's butler. However, his talents to find people to design, market and sell the gun is without a doubt laudible. The only two firearms that every US journalist knows is either an AK or a Glock. Now you can build both ... from the same shovel.

How Glocks work

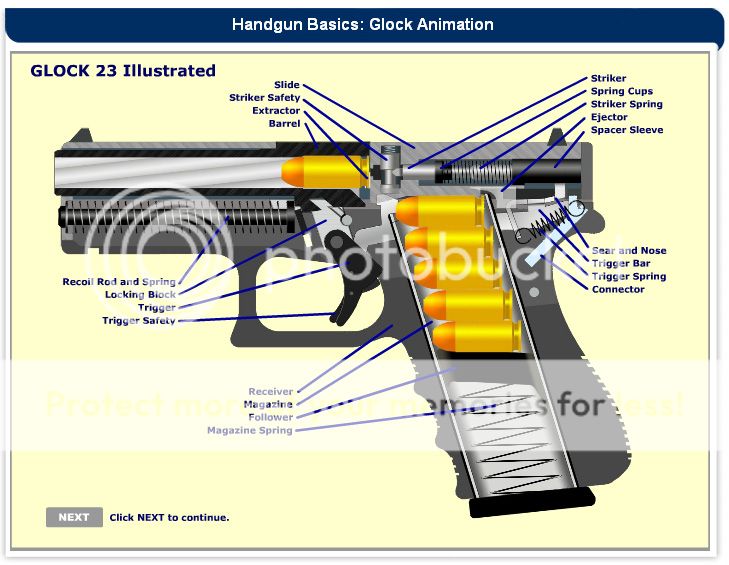

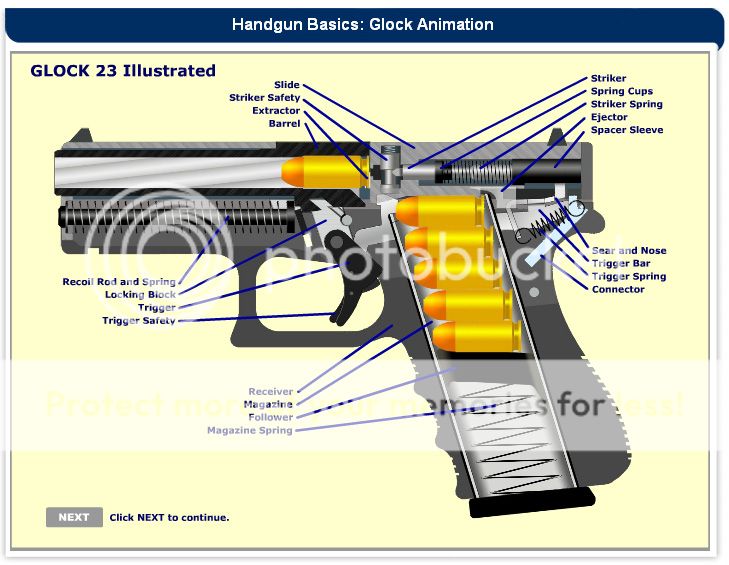

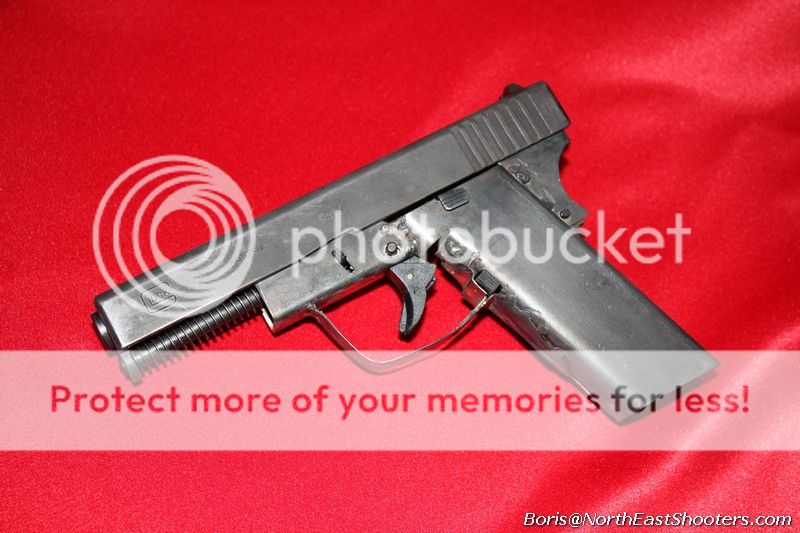

As I have mentioned, Glocks use St. JMB's design to lock barrel in the slide, making the slide pretty much a firearm in itself as it also houses the striker. Frame serves secondary functions like holding the mag, extractor and FCG. The rails guide the slide back and forth. "Locking block" actually unlocks the barrel and has nothing to do with holding it locked.

For those who want to learn how Glocks work and play with it in the safety of your mom's basement, there is an awesome interactive Flash app that allows you to take a closer look how components work, fire the gun etc. It's located on Genitron's website: (some virtual licensing may be required to fire virtual guns)

Glock Pistol Animation

Here is a screenshot of the app:

don't worry about this being Glock23 ... 23, 32, it's the same shit in different dimensions.

I want to give a special thanks to Dark Lord Marsha Cloacaly and the Soviet Rupublic of mAssucktaxachussetts (with fake "Indian" Lizzy on its seal) for making it all possible. Without you, I'd just buy a gen4 Glock.

"Rifles do have a place in the survivalist’s arsenal, and a very important one. But you have to understand that 90% of the time, the handgun will be the weapon you have available when you need one."

Thoughts On Urban Survival by Ferfal

Das Eiserne Glock

The Iron Glock

Why Glock ?

History of Glock

How Glocks work

Building your Glock

- Fore-piece, steps F 1 - 3

- Aft section, steps A 1 - 3

- Mid section, steps M 1 - 3

- Joing, steps J 1 - 7

Finishing up

- Mech-Tech upper for your Iron Glock frame

Common Issues and Problems

Vids

List of updates

| Date | Steps | What's updated |

|---|---|---|

| 7-8-13 | Step M2 | Added pictures on welding the grip together |

| 7-10-13 | Step F3 | Added jig description for marking the hole |

| 7-12-13 | Step F1 | Added pics and dimensions for fitting the forward piece-rails |

| 7-26-13 | Step J5 | Added pics and dimensions for fitting the slide stop |

| 8-14-13 | Finishing Up + Movies | Mech-Tech in finishing up section + more vids of shooting with Mech-Tech upper |

| 10-08-13 | J5 | Added guides for all three kits, where to cut the slide stop slot and distances. |

Why Glock?

Since the dawn of Man, at any time, in any nation, people who bear arms freely without infringements were called FREE MEN. Since the dawn of Man, at any time, in any nation, people who were restricted or banned from bearing arms were called SLAVES or by any other name.

I started to look for a BIY pistol for the time when zombies are not quite roaming the streets yet, but currency already has little value and we have a bunch of crooks running .gov. In other words, cheap, realiable pistol capable of variety of calibers with parts that could be found easily and could interchange. ... also it can't be made out of aluminum (like a lawn chair or AR)

My choice fell on Glocks, the plastic AKs of the pistol cosmos. Glock is the opposite of any typical German gun: simple, loose tolerances making it reliable by even Russian standards, most parts interchange between models and it sucks to shoot. Glocks have many advantages. There are so many of them everywhere that I often check my Krapfen Strudel for Glock parts after I take my morning dump. Several aftermarket companies work day and night making a whole bunch more. Hi cap mags are fairly cheap and very common, but the best part is that having one frame you can switch the slide in a few seconds and shoot 22lr, 9mm, 40 or 357.

If you use terms for pseudo-firearms, ... like ARs, Glock has an upper or the slide that could be changed quickly, like 2 sec quickly without breaking any aluminum hinges (aluminum like in a lawnchair). This upper-slide comes in variety of calibers. The "lower" frame is a piece of plastic that grips Glock's LPK. Amazingly as always, only the plastic frame is considered to be the firearm. LPK that is FCG and few other random bits are typically $75 and are not regulated. Slides are not regulated either and can go anywhere from around $250 and up. With mAss Glock prices for gen 4s sailing north of $800, this is a very attractive option.

four calibers

one "glock" to shoot them all

... Das Eiserne Glock!

History of Glock

Gaston Glock started his career designing curtain rods. He stamped this fruity shit on a Russian stamping press that supposably was left by Kalashnikov himself when he was kicking ass on his tour through Europe. Over the years, vodka vapors used in lubrication and the sheer Awesome radiating from the press kept accumulating until it reached critical mass and made Gaston marry huge boobs with a chick that were less than half of Gaston's age and then pay a ton of money to design Glock17. G17 combined two awesome concepts: St. JMB's locking barrel design and Kalashnkov's principles of manufacturing cheap, reliable guns. It's like US made vodka: it tastes good while making you a filthy capitalist pig in the process.

While Glock has become an iconic firearm, Gaston's skill as an engineer are probably on par with St. JMB's butler. However, his talents to find people to design, market and sell the gun is without a doubt laudible. The only two firearms that every US journalist knows is either an AK or a Glock. Now you can build both ... from the same shovel.

How Glocks work

As I have mentioned, Glocks use St. JMB's design to lock barrel in the slide, making the slide pretty much a firearm in itself as it also houses the striker. Frame serves secondary functions like holding the mag, extractor and FCG. The rails guide the slide back and forth. "Locking block" actually unlocks the barrel and has nothing to do with holding it locked.

For those who want to learn how Glocks work and play with it in the safety of your mom's basement, there is an awesome interactive Flash app that allows you to take a closer look how components work, fire the gun etc. It's located on Genitron's website: (some virtual licensing may be required to fire virtual guns)

Glock Pistol Animation

Here is a screenshot of the app:

don't worry about this being Glock23 ... 23, 32, it's the same shit in different dimensions.

Last edited:

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

![Rockon [rockon] [rockon]](/xen/styles/default/xenforo/smilies.vb/020.gif)