RugerSlinger

NES Member

First off, has anyone made one with success?

I am on my first prototype and it is going OK. I am going to get bashed because I dont have any pics right now but I hope to have some up tomorrow. It is very crude looking right now but I really wanted to see if it was possible before I made it pretty.

I have the basics down right now,

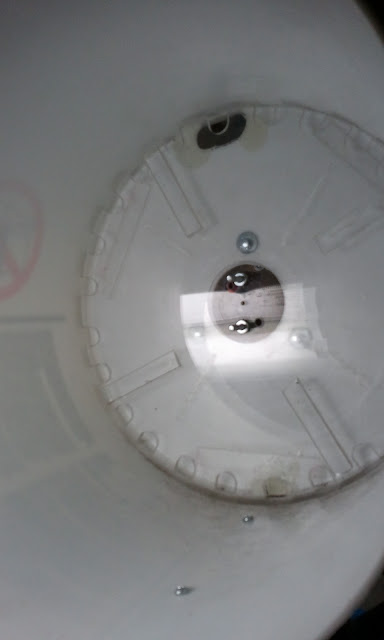

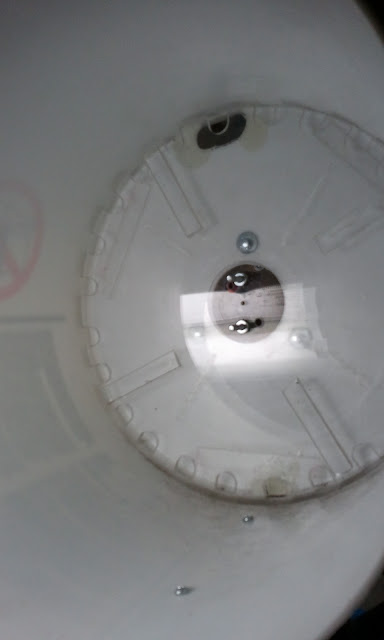

I used a 5 gallon bucket as the container

I have some thin Plexiglass and some 1/4" thick for the shell holders

I used the thin plexiglass as a shoot down to the holding tube on my 650

I have a few different switches that I haven't figured out how to use yet. A normal micro switch and a beam break switch out of a paintball hopper. If someone knows how to make a beam break one, please oh please help me with this because this is what I really want to do.

I have about 30 hours into this thing already so it isn't worth engineering this thing yourself. If I do get it to work i will be glad to help others make them if interested.

As of right now I am at a stand still waiting on a new motor I just ordered but my current setup works. I am using a small motor out of an old circular display case that makes it spin. It is low enough RPM but not enough torque, I can load about a hand full of 40s and 45s and it will work perfectly. It loads them all standing strait up faster than I can reload them, I have been using it like this because I am too impaitient to wait for the new motor. I have already been through 2 different motors. The first one I used was a window motor out of an 04 Grand Am. It was way more torque than I needed but it was way to fast. I tried lowering the voltage but then it didn't have enough balls.

I am hoping this new motor works because I ordered 3 of them, that is how confident that it will work. I am planning on making 2 for myself for my 650s and not sure what to do with the spare motor right now. I hope they will be in by Friday so I can have a final product done over the weekend.

I will post some pics and vids tomorrow.

BTW I only have $20 into this project right now but with the new motor I will be in for almost $60. I was trying to build it for under $30. Now I have way to much time into this to give up and buy the dillon one.![Hmm [hmmm] [hmmm]](/xen/styles/default/xenforo/smilies.vb/009.gif)

Please any suggestions would be appreciated.

Thanks

Andrew

I am on my first prototype and it is going OK. I am going to get bashed because I dont have any pics right now but I hope to have some up tomorrow. It is very crude looking right now but I really wanted to see if it was possible before I made it pretty.

I have the basics down right now,

I used a 5 gallon bucket as the container

I have some thin Plexiglass and some 1/4" thick for the shell holders

I used the thin plexiglass as a shoot down to the holding tube on my 650

I have a few different switches that I haven't figured out how to use yet. A normal micro switch and a beam break switch out of a paintball hopper. If someone knows how to make a beam break one, please oh please help me with this because this is what I really want to do.

I have about 30 hours into this thing already so it isn't worth engineering this thing yourself. If I do get it to work i will be glad to help others make them if interested.

As of right now I am at a stand still waiting on a new motor I just ordered but my current setup works. I am using a small motor out of an old circular display case that makes it spin. It is low enough RPM but not enough torque, I can load about a hand full of 40s and 45s and it will work perfectly. It loads them all standing strait up faster than I can reload them, I have been using it like this because I am too impaitient to wait for the new motor. I have already been through 2 different motors. The first one I used was a window motor out of an 04 Grand Am. It was way more torque than I needed but it was way to fast. I tried lowering the voltage but then it didn't have enough balls.

I am hoping this new motor works because I ordered 3 of them, that is how confident that it will work. I am planning on making 2 for myself for my 650s and not sure what to do with the spare motor right now. I hope they will be in by Friday so I can have a final product done over the weekend.

I will post some pics and vids tomorrow.

BTW I only have $20 into this project right now but with the new motor I will be in for almost $60. I was trying to build it for under $30. Now I have way to much time into this to give up and buy the dillon one.

![Hmm [hmmm] [hmmm]](/xen/styles/default/xenforo/smilies.vb/009.gif)

Please any suggestions would be appreciated.

Thanks

Andrew

Last edited by a moderator: