The Goose

NES Member

I recently acquired a couple of old British Martini Henry rifles chambered in .577/450 and I would like to shoot them. The cost of loaded ammo is prohibitive to say the least and often the bullets are the wrong size for a given rifle. Even the brass runs $5.00 - $8.00 each, if you can find it. After some web searching on some Martini Henry forums and Youtube I came up with a way to form the brass at a somewhat reasonable cost, although labor intensive. I know that this topic will interest only a very few, but I thought I would share how I am doing it with the equipment I have or have put together. Others may have better ways or better equipment, but so far this is working for me.

First of all Magtech makes a 24 gauge brass shotshell that sells for just under $25 for 25.

It needs to be trimmed to 2.283" for the purpose. In the past I have used a dremel to trim brass and have only trimmed close to the correct length and then used a case trimmer to get the exact length and a smooth cut. I do not have a case trimmer large enough for this brass ( I doubt anyone does) so I need a smooth and precise cut right out of the gate. I found an inexpensive tube cutter with a socket placed inside of the brass supports it for a nice cut and the screwdriver type handle makes it easy to turn. So I scribe the brass wit my calipers, cut it and then rub it accross some sandpaper.

Next I anneal the end of the brass. I use a rod in my electric drill and spin the brass over the flame for 5 - 6 seconds and drop into cold water.

Since I also load .577 Snider I use the Snider sizing die to begin the sizing process. Because the Snider brass is only 2" long I back the die out a few turns for the initial reduction. I use Lee sizing lube.

Now I insert the .577/450 sizing die into the press. I only twist it in until the very first thrad catches enough to hold the die in place. Then I slowly work the brass up into it until it is flush. Any binding and I back off and slowly begin again. After a few ruined brass I got the "feel".

This is how the brass looks at this point.

Now I began slowly advancing. There are six flats on the die nut and I go a 1/6 turn each time and then raise th ram adding lube as needed. This is slow, but very reliable. Every so many turns I check the brass for signs of wrinkling or crushing. At about the half way point I anneal the brass for 5 - 6 seconds again and then continue until the ramm is all the way up. Here is the end result.

I have my brass and the loading portion begins. At this point I expand the neck and insert a large pistol primer. Next I load 85 grains of Goex 2F black powder down a drop tube.

There is room in the case so I need a filler. I want to get some carded wool like the original, but for right now I am useing some cotton ball with a Walters .060 vegetable fiber wad on top. I slightly compress it with a punch.

My bullet is a .468 diameter from an RCBS mold and I use a .468 sizing die in my Lyman lubrisizer that I got from Buffalo Arms Co. The lube is a blackpowder lube made by Sagebrush. This is a good size bullet for most British made Martini Henry's although of course you should slug your bore to find out. There is a good video on Youtube on how to do this and in particular how to measure the size for the MH. As a side note the Nepalese rifles such as the Gahendra can vary widely in bore dimensions.

Below is the end result. I will post some range reports as I go along. Now that I have the basic idea down I can start playing with loads and working on accuracy. I only have a dozen pieces of brass made up right now, but slowly over time that will increase. Hope you found this interestig.

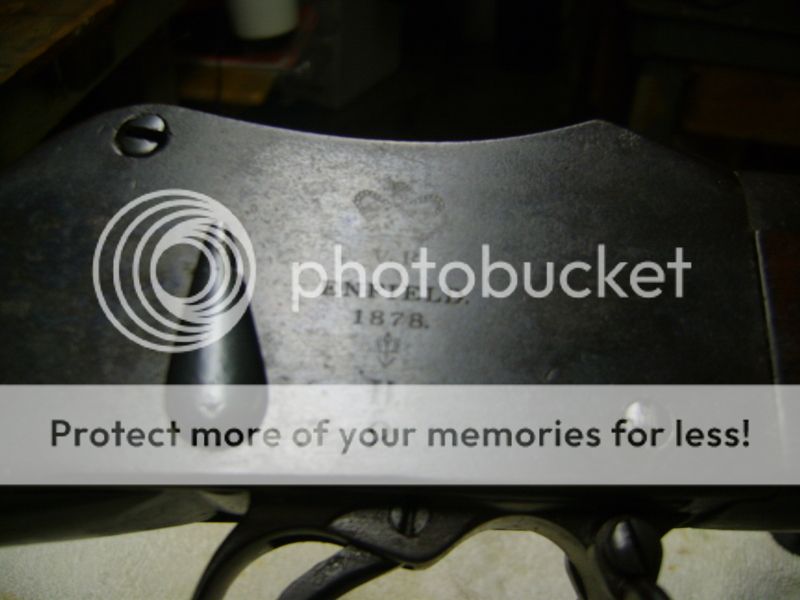

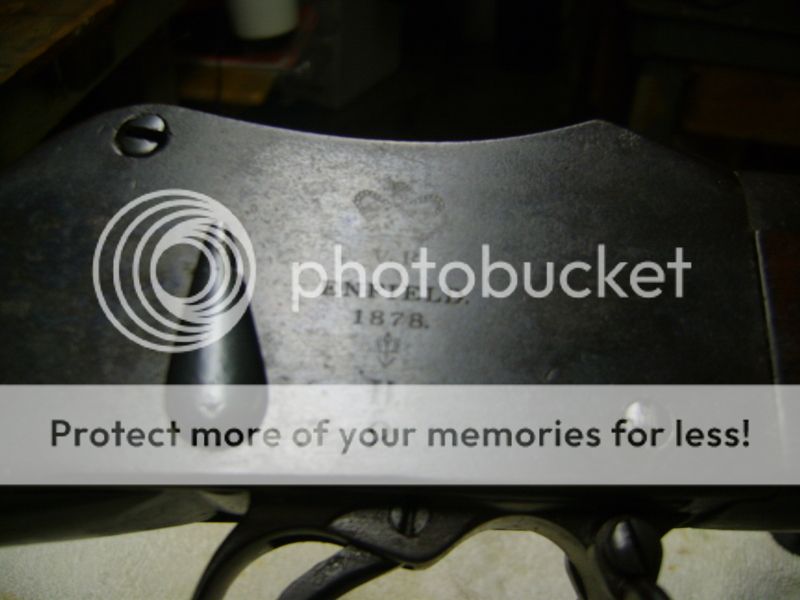

My Martini Henry MK II

First of all Magtech makes a 24 gauge brass shotshell that sells for just under $25 for 25.

It needs to be trimmed to 2.283" for the purpose. In the past I have used a dremel to trim brass and have only trimmed close to the correct length and then used a case trimmer to get the exact length and a smooth cut. I do not have a case trimmer large enough for this brass ( I doubt anyone does) so I need a smooth and precise cut right out of the gate. I found an inexpensive tube cutter with a socket placed inside of the brass supports it for a nice cut and the screwdriver type handle makes it easy to turn. So I scribe the brass wit my calipers, cut it and then rub it accross some sandpaper.

Next I anneal the end of the brass. I use a rod in my electric drill and spin the brass over the flame for 5 - 6 seconds and drop into cold water.

Since I also load .577 Snider I use the Snider sizing die to begin the sizing process. Because the Snider brass is only 2" long I back the die out a few turns for the initial reduction. I use Lee sizing lube.

Now I insert the .577/450 sizing die into the press. I only twist it in until the very first thrad catches enough to hold the die in place. Then I slowly work the brass up into it until it is flush. Any binding and I back off and slowly begin again. After a few ruined brass I got the "feel".

This is how the brass looks at this point.

Now I began slowly advancing. There are six flats on the die nut and I go a 1/6 turn each time and then raise th ram adding lube as needed. This is slow, but very reliable. Every so many turns I check the brass for signs of wrinkling or crushing. At about the half way point I anneal the brass for 5 - 6 seconds again and then continue until the ramm is all the way up. Here is the end result.

I have my brass and the loading portion begins. At this point I expand the neck and insert a large pistol primer. Next I load 85 grains of Goex 2F black powder down a drop tube.

There is room in the case so I need a filler. I want to get some carded wool like the original, but for right now I am useing some cotton ball with a Walters .060 vegetable fiber wad on top. I slightly compress it with a punch.

My bullet is a .468 diameter from an RCBS mold and I use a .468 sizing die in my Lyman lubrisizer that I got from Buffalo Arms Co. The lube is a blackpowder lube made by Sagebrush. This is a good size bullet for most British made Martini Henry's although of course you should slug your bore to find out. There is a good video on Youtube on how to do this and in particular how to measure the size for the MH. As a side note the Nepalese rifles such as the Gahendra can vary widely in bore dimensions.

Below is the end result. I will post some range reports as I go along. Now that I have the basic idea down I can start playing with loads and working on accuracy. I only have a dozen pieces of brass made up right now, but slowly over time that will increase. Hope you found this interestig.

My Martini Henry MK II