I finally received all the parts I was waiting for to finish this rifle.

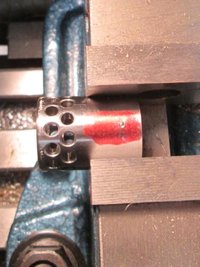

First I pinned the MD on. (normally I silver solder the MD on, but that was not an option with a SS barrel) I spot drilled it then attached to the barrel, finished drilling the hole and pinned it. I do not have a TIG so I took it to a buddy who does.

Once the MD was finished I polished the feed ramps and installed the barrel on the upper.

First I pinned the MD on. (normally I silver solder the MD on, but that was not an option with a SS barrel) I spot drilled it then attached to the barrel, finished drilling the hole and pinned it. I do not have a TIG so I took it to a buddy who does.

Once the MD was finished I polished the feed ramps and installed the barrel on the upper.

![Thumbs Up [thumbsup] [thumbsup]](/xen/styles/default/xenforo/smilies.vb/044.gif)