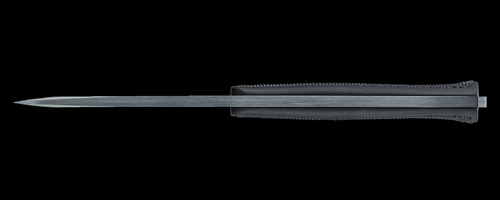

Thinking of pulling the trigger on an Fallknivin SAF pilot survival knife....Swedish AF issue circa 95. Impressions ?

-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

FallKniven knives....anyone ?

- Thread starter Rat187

- Start date

Those look like nice utility knives that could fight if you needed them to. I have an Emerson PUK that fills this role nicely, I think more handguard, less convex grind and more v-grind.

Depending on the job yours looks quite useful.

Depending on the job yours looks quite useful.

Could some enlighten me on the plus & minuses of knife edges ?

It's all in the grind.

The edge itself is just the area where the user runs the knife over the stone. But the grind, put there by the factory, has a lot of variation. It's how the factory tapers the steel toward the edge. It's usually either convex (bulged) or concave (dished). Some are straight (v-grind), which is what it sounds like: a single flat angle toward the edge.

Generally, concave grinds are easier to sharpen and cheaper to produce. Convex grinds tend to hold an edge longer, all else being equal. A hard-use woodsman's knife, for chopping or batonning. does better with a convex (or straight) grind, while you'd buy concave for something you'll be using for tasks requiring more sharpness and less durability.

Think of the difference between a cleaver and a chef's knife.

Last edited:

- Joined

- Sep 10, 2009

- Messages

- 41,857

- Likes

- 79,509

F1XB looks very nice...

Description

Your X-knife is the strongest, sharpest and safest stainless steel knife in production. If your life is in danger, you can always rely on your X-knife. It is designed to withstand all the stresses applied by the human hand, which means that it is virtually indestructible. It assumes, however, that you are careful with the knife and that it is used as intended, namely as a sharp precision tool.

The basis of the X-knife’s strength lies in the laminated cobalt steel, and also in the well-thought-out construction in which break zones have been eliminated. Together with the hand-shaped convex edge, the X-knife is a concept that beats everything else in the world in terms of safety and comfort.

A few words about the all-black version: This surface is the hardest we have ever encountered. Although we really tried to wear down the black coating with the toughest, driest curly birch we could find, we never succeeded in getting holes in this extremely hard, durable surface. Still, we cannot guarantee that it will stay for time and eternity, after all, the blade can be ground and certainly bites a diamond or ceramic stone on the surface. But you have probably never met a harder surface, the hardness is at 2400 HV (Vickers) or around HRC 83.

In our usual way, we have put a lot of energy into designing a safe knife sheath, which is actually where the knife will spend most of its time. The design of the sheath determines the access to the knife, and here we have really put all our efforts in order to get a safe sheath that allows easy access to the knife. The sheath has both a transport lock (the folding bracket with a strap) and a working safety detail that allows the knife to be in place until you decide to use it. It is a bit a belt-and-braces approach, but we like putting safety first – a lost knife is of no use. The transport lock will therefore allow the knife to be fastened tip-up or tip-down on the body or on your equipment without any risk.

As an accessory, the knife sheath is available with a stainless clip that allows you to easily carry the knife on your waist belt. The advantages are several – including that you can easily remove and stow your knife. When belt-mounted, the knife will hang vertically, a few centimeters lower than the belt, allowing it to be accessed even if wearing a backpack or long jacket. The articulation in this sheath system allows the

wearer to move the knife and sheath to one side when seated or driving a vehicle.

Overall: We won’t be surprised if people starts recognizing the X-knife as the world’s most thoroughly thought-out knife concept where no corner has been cut, nothing spared, to bring out the very best from an ergonomic and safety point of view. The knife is sharp and strong, the sheath is smart and safe. So, what more can you ask for? Well, we’ve created the knife to be really good looking too!

If you want a leather sheath for this knife, we recommend the SK1el. Click here to get to the SK1el.

There is also a strap pack available for the X-sheaths. Click here to get to the Strap pack.

Description

Your X-knife is the strongest, sharpest and safest stainless steel knife in production. If your life is in danger, you can always rely on your X-knife. It is designed to withstand all the stresses applied by the human hand, which means that it is virtually indestructible. It assumes, however, that you are careful with the knife and that it is used as intended, namely as a sharp precision tool.

The basis of the X-knife’s strength lies in the laminated cobalt steel, and also in the well-thought-out construction in which break zones have been eliminated. Together with the hand-shaped convex edge, the X-knife is a concept that beats everything else in the world in terms of safety and comfort.

A few words about the all-black version: This surface is the hardest we have ever encountered. Although we really tried to wear down the black coating with the toughest, driest curly birch we could find, we never succeeded in getting holes in this extremely hard, durable surface. Still, we cannot guarantee that it will stay for time and eternity, after all, the blade can be ground and certainly bites a diamond or ceramic stone on the surface. But you have probably never met a harder surface, the hardness is at 2400 HV (Vickers) or around HRC 83.

In our usual way, we have put a lot of energy into designing a safe knife sheath, which is actually where the knife will spend most of its time. The design of the sheath determines the access to the knife, and here we have really put all our efforts in order to get a safe sheath that allows easy access to the knife. The sheath has both a transport lock (the folding bracket with a strap) and a working safety detail that allows the knife to be in place until you decide to use it. It is a bit a belt-and-braces approach, but we like putting safety first – a lost knife is of no use. The transport lock will therefore allow the knife to be fastened tip-up or tip-down on the body or on your equipment without any risk.

As an accessory, the knife sheath is available with a stainless clip that allows you to easily carry the knife on your waist belt. The advantages are several – including that you can easily remove and stow your knife. When belt-mounted, the knife will hang vertically, a few centimeters lower than the belt, allowing it to be accessed even if wearing a backpack or long jacket. The articulation in this sheath system allows the

wearer to move the knife and sheath to one side when seated or driving a vehicle.

Overall: We won’t be surprised if people starts recognizing the X-knife as the world’s most thoroughly thought-out knife concept where no corner has been cut, nothing spared, to bring out the very best from an ergonomic and safety point of view. The knife is sharp and strong, the sheath is smart and safe. So, what more can you ask for? Well, we’ve created the knife to be really good looking too!

If you want a leather sheath for this knife, we recommend the SK1el. Click here to get to the SK1el.

There is also a strap pack available for the X-sheaths. Click here to get to the Strap pack.

ReluctantDecoy

NES Member

I hear great things about this brand as a real world work knife, not just an ornamental piece or mass produced brand. I've been a MoraKniv person for that same reason. Nothing flashy, just a good work knife. I feel this might be the same. However, that steel type--I don't think I've ever used it. LAM.COS? Cobalt steel?

Enbloc you dog !! Guess I'll be using my unused ESSEE 4 as a tactical steak knife

Just bought the Fallkniven F1xb with locking kydex sheath should arrive next week ....joy joy....lol

Just bought the Fallkniven F1xb with locking kydex sheath should arrive next week ....joy joy....lol

This is my fourth knife purchase in 8 weeks...lol

BTDT.

- Joined

- Sep 10, 2009

- Messages

- 41,857

- Likes

- 79,509

Yep, I'm a firm believer in buying something I can't 'make'...This is my fourth knife purchase in 8 weeks...lol

What pray tell is laminated knife steel....?

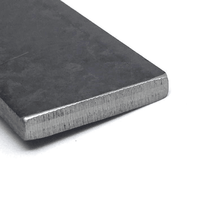

If you look real close at enbloc's second pic - the spine. You can almost make out the center and two outer layers. -not sure how they bind those layers.

Anywho - my assumption is they used a more stiff metal on the outer layers for strength, and a softer metal down the center for easier sharpening....or it could be vice-versa hahaha.

But, you get the jist.

HAHAHA - based on enbloc's synchronized post, it's vice-versa.

and...nice looking knife OP!

- Joined

- Sep 10, 2009

- Messages

- 41,857

- Likes

- 79,509

If you look real close at enbloc's second pic - the spine. You can almost make out the center and two outer layers. -not sure how they bind those layers.

Anywho - my assumption is they used a more stiff metal on the outer layers for strength, and a softer metal down the center for easier sharpening....or it could be vice-versa hahaha.

But, you get the jist.

HAHAHA - based on enbloc's synchronized post, it's vice-versa.

and...nice looking knife OP!

We have some Blade Makers and Smiths here on NES and I'm sure they will build this 'metallurgy' data chain up...

Interesting blade making technique. This could get expensive....lol

I realized need a machete for clearing small saplings around the property and greeting political canvasser's with.

I realized need a machete for clearing small saplings around the property and greeting political canvasser's with.

Interesting blade making technique. This could get expensive....lol

I realized need a machete for clearing small saplings around the property and greeting political canvasser's with.

I'll help ya spend money.

Actually, these are reasonably priced. I got a Golok a couple years back. The thing is stout. The grind is a little obtuse near the handle and changes as you proceed up the blade.

MACHETES | CONDOR Tool & Knife

- Joined

- Sep 10, 2009

- Messages

- 41,857

- Likes

- 79,509

ESEE!

ESEE Knives - Expat Darien Machete with Sheath

$59.95 w/ Lifetime Warranty

($100.76 at ESEE)

This machete is closer to a Bolo style machete than a Latin style. Both have their positives and negatives, but this style is well suited for a Northeast forest,

whereas a 'Latin' machete is "all jungle"...

The Expat Darien Machete

From ESEE

The new Darien machete from Expat Knives is named after the Darien province on the southeastern end of Panama that borders Colombia. The area bordering Colombia is known as the Darien Gap. The missing link in the Pan-American Highway, the Darien Gap is an approximate 66 mile stretch of wilderness where the highway could not be completed for various reasons.

In the last blog, I promised an overview of the Darien, so here it is. And no, I didn’t break it! When I picked it up for the first time I immediately noticed how well balanced it seemed. Similar in size to our Junglas, the Darien features a 1075 carbon steel blade that is just over 12“ in length and immediately gives you the desire to go put it to work. I finally got the chance after a Land Navigation class at the farm.

The guys in El Salvador really know how to make good machetes and the Darien is no exception. First, I did some light chopping just to get a feel for the blade. The overall thickness and grind on the blade easily chopped through Chinese Privet up to an inch thick with a single stroke. I then wanted to see how many strikes it would take to get through a small pine tree that needed to come down. The first bit very deeply and the second from the opposite side dropped the tree in no time. Next, I used the Darien to chop through a thicker dead pine log which it handled without any issues.

In the past, I have batonned with various machetes. Usually it was because it was what I had with me at the time and was a matter of convenience, either to make fire or needing material of a certain size while teaching a class. With machetes being plenty long enough and not overly hardened to the point of becoming fragile, they may flex at times but have always returned to true. I wanted to see if the Darien would hold up to this task. I grabbed a piece of oak at bum-camp (area at Randall’s Adventure & Training where most of the hands-on skills are taught) and went to work. The Darien did not disappoint.

With larger blades, it’s fairly easy to make feathersticks by driving the blade into a log or stump tip down, and then pulling the wood into the edge. The Darien came razor sharp and had no trouble slicing the shavings as thin as I wanted them. The spine throws plenty of sparks from a ferro rod, so this is another plus.

If I have any complaints, it’s the sheath. But being in the business, I understand that to offer a machete with a nice Kydex sheath would almost double the price. In the Amazon you seldom see a sheath anywhere, even though machetes are a way of life. For the folks wanting a better sheath for it there are plenty of aftermarket makers who will be making sheaths eventually.

The Darien is a great mid-sized blade that can be strapped to a pack or thrown in a vehicle. It can handle simple camp chores or even tackle bigger tasks if required. When paired with a smaller fixed blade or folder, you would have almost all of your bases covered. If I was clearing a large area or bushwhacking a trail through thick vegetation, I would still prefer a full-size machete of course. However, if you are looking for a chopper that won’t take up too much room but can still handle heavy work, I think the Darien is a great option for you.

Patrick Rollins

Oh, and it comes with the ESEE "No Questions Asked Lifetime Warranty"...

WARRANTY:

ESEE knives are made with absolute attention to detail using the finest raw materials and care during the manufacturing process. We stand behind our knives with a 100% unconditional lifetime guarantee. If your ESEE knife should ever break, we will repair or replace it. This warranty follows the knife throughout its life, anywhere in the world. No sales receipt or warranty registration required.

The Darien features an ergonomic Micarta handle for all day comfort and a 12.38” blade (18.18” overall). It weighs a mere 15.5 ounces and comes standard with a rugged, tan colored canvas sheath. With 1075 steel construction, the Darien is a chopping machine whether in the Amazon or the jungle in your own backyard. Same "no questions asked" warranty as the standard ESEE® Knives line.

Specs:

ESEE Knives - Expat Darien Machete with Sheath

$59.95 w/ Lifetime Warranty

($100.76 at ESEE)

This machete is closer to a Bolo style machete than a Latin style. Both have their positives and negatives, but this style is well suited for a Northeast forest,

whereas a 'Latin' machete is "all jungle"...

The Expat Darien Machete

From ESEE

The new Darien machete from Expat Knives is named after the Darien province on the southeastern end of Panama that borders Colombia. The area bordering Colombia is known as the Darien Gap. The missing link in the Pan-American Highway, the Darien Gap is an approximate 66 mile stretch of wilderness where the highway could not be completed for various reasons.

In the last blog, I promised an overview of the Darien, so here it is. And no, I didn’t break it! When I picked it up for the first time I immediately noticed how well balanced it seemed. Similar in size to our Junglas, the Darien features a 1075 carbon steel blade that is just over 12“ in length and immediately gives you the desire to go put it to work. I finally got the chance after a Land Navigation class at the farm.

The guys in El Salvador really know how to make good machetes and the Darien is no exception. First, I did some light chopping just to get a feel for the blade. The overall thickness and grind on the blade easily chopped through Chinese Privet up to an inch thick with a single stroke. I then wanted to see how many strikes it would take to get through a small pine tree that needed to come down. The first bit very deeply and the second from the opposite side dropped the tree in no time. Next, I used the Darien to chop through a thicker dead pine log which it handled without any issues.

In the past, I have batonned with various machetes. Usually it was because it was what I had with me at the time and was a matter of convenience, either to make fire or needing material of a certain size while teaching a class. With machetes being plenty long enough and not overly hardened to the point of becoming fragile, they may flex at times but have always returned to true. I wanted to see if the Darien would hold up to this task. I grabbed a piece of oak at bum-camp (area at Randall’s Adventure & Training where most of the hands-on skills are taught) and went to work. The Darien did not disappoint.

With larger blades, it’s fairly easy to make feathersticks by driving the blade into a log or stump tip down, and then pulling the wood into the edge. The Darien came razor sharp and had no trouble slicing the shavings as thin as I wanted them. The spine throws plenty of sparks from a ferro rod, so this is another plus.

If I have any complaints, it’s the sheath. But being in the business, I understand that to offer a machete with a nice Kydex sheath would almost double the price. In the Amazon you seldom see a sheath anywhere, even though machetes are a way of life. For the folks wanting a better sheath for it there are plenty of aftermarket makers who will be making sheaths eventually.

The Darien is a great mid-sized blade that can be strapped to a pack or thrown in a vehicle. It can handle simple camp chores or even tackle bigger tasks if required. When paired with a smaller fixed blade or folder, you would have almost all of your bases covered. If I was clearing a large area or bushwhacking a trail through thick vegetation, I would still prefer a full-size machete of course. However, if you are looking for a chopper that won’t take up too much room but can still handle heavy work, I think the Darien is a great option for you.

Patrick Rollins

Oh, and it comes with the ESEE "No Questions Asked Lifetime Warranty"...

WARRANTY:

ESEE knives are made with absolute attention to detail using the finest raw materials and care during the manufacturing process. We stand behind our knives with a 100% unconditional lifetime guarantee. If your ESEE knife should ever break, we will repair or replace it. This warranty follows the knife throughout its life, anywhere in the world. No sales receipt or warranty registration required.

The Darien features an ergonomic Micarta handle for all day comfort and a 12.38” blade (18.18” overall). It weighs a mere 15.5 ounces and comes standard with a rugged, tan colored canvas sheath. With 1075 steel construction, the Darien is a chopping machine whether in the Amazon or the jungle in your own backyard. Same "no questions asked" warranty as the standard ESEE® Knives line.

Specs:

- Overall Length: 18.18"

- Blade Length: 12.38"

- Maximum Thickness: .094"

- Steel: 1075 Carbon, 54-56 Rc.

- Weight (Blade Only): 15.5 Ounces

- Weight (Blade and Sheath): 20 Ounces

- Handle: Micarta

- Sheath: Canvas

- Made In El Salvador

Last edited:

ReluctantDecoy

NES Member

What pray tell is laminated knife steel....?

Depends on the context. Sometimes it means a metal sandwich where two or more metals of different properties are fused together to form one blade. The center metal might take to sharpening better while the outside is stronger metal for structural integrity. But in it's most basic meaning, it just means welded or fused together, even if just one metal that's been folded in part of the forge process. If that fold comes undone while hammering it away in an attempt to make it one solid piece, that's said to be de-lamination.

- Joined

- Sep 10, 2009

- Messages

- 41,857

- Likes

- 79,509

Link please!I've never spent that much on a machete. I've bought them at all price points up to about $40, and the best one I've ever had cost like $8.

![ROFL2 [rofl2] [rofl2]](/xen/styles/default/xenforo/smilies.vb/035.gif)

I've never spent that much on a machete. I've bought them at all price points up to about $40, and the best one I've ever had cost like $8.

It's only play money...

Share:

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif) ...I think I'll skip an amazon purchase

...I think I'll skip an amazon purchase