Golddiggie

NES Member

As some of you know, I've been working to anodize aluminum here at home. I've gone through a couple of configuration, and process, tweaks and have it working really well. I started off with looking to use sulfuric acid for the electrolyte. But after reading up about the hazards involved, I decided to not go that route. Instead I was able to use sodium bisulfate (info found here) for the electrolyte.

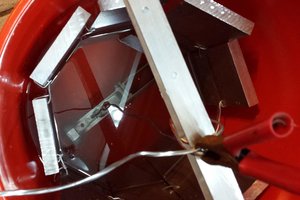

I ended up using 3.5 gallon buckets (thanks Gator9329) for the etc, and dye tanks. A 5 gallon bucket is my anodizing tank due to getting a better cathode setup. For the water, I'm getting it from the filtration system under the sink (goes down to .2 micron) which is sent through a DI filter before being used. Couple that with an old Craftsman battery charger (from the early 80's) and I have a working system. You won't be able to use a newer battery charger due to the protection circuits inside them.

Last night I re-anodized the lower for my 300 Blackout pistol. I had previously anodized it without any dye bath. It was ok initially, but after seeing more lowers, and what other people have done, I decided mine needed some color. So, after stripping the LPK out of it, giving it a quick cleaning and soak in denatured alcohol, I set it into the etch tank. That's a 2-4% solution of sodium hydroxide. After about 7-8 minutes in that tank, the previous anodizing was removed. Removed from that tank, rinsed with DI water, and then put it into the anodizing tank. Connected the battery charger up to the cathode and anode and set it to run. After about an hour the reactions had stopped, which means all that can be done has been done. Removed, rinsed again with DI water, and set to sit in the dye bath. I checked on it at 20 minutes, not the color I wanted, back into the pool. At ~45 it still needed some more. I started the sealing water to boil (had previously gotten it up to temp, then stopped when it became clear I would need more time in the dye bath). Checked after about an hour total and it was looking really good. Added the sealing solution to the boiling water, mixed fully and then placed the now dyed lower into the pot (after rinsing the lower with more DI water). Let it boil for 20 minutes, removed, rinsed with more DI water and then set to dry overnight.

Result:

300 Blackout pistol before Saturday night:

300 Blackout pistol this morning after anodizing/dyeing last night:

Since the first picture I had also wrapped the pistol buffer tube with paracord. Just to act as padding between the metal tube and me when doing a cheek weld (easier for me than putting to my shoulder).

Technically you can dye the aluminum any color you can mix up. You can get dye from Caswell if you want, or use Rit dye from the fabric store.

I did reserve the sealing solution this time. I have a good amount of what you add to the water, but figured why not save it. I should be able to get at least a few more lowers out of the same batch. I have found that stripping anodizing off of parts fouls the NaOH solution pretty fast. But, it's easy to mix up more. If you mix it on the stronger side, put it near a fresh air source and put a loose lid over that bucket. The part will turn a dark grey when the NaOH has done it's job.

I ended up using 3.5 gallon buckets (thanks Gator9329) for the etc, and dye tanks. A 5 gallon bucket is my anodizing tank due to getting a better cathode setup. For the water, I'm getting it from the filtration system under the sink (goes down to .2 micron) which is sent through a DI filter before being used. Couple that with an old Craftsman battery charger (from the early 80's) and I have a working system. You won't be able to use a newer battery charger due to the protection circuits inside them.

Last night I re-anodized the lower for my 300 Blackout pistol. I had previously anodized it without any dye bath. It was ok initially, but after seeing more lowers, and what other people have done, I decided mine needed some color. So, after stripping the LPK out of it, giving it a quick cleaning and soak in denatured alcohol, I set it into the etch tank. That's a 2-4% solution of sodium hydroxide. After about 7-8 minutes in that tank, the previous anodizing was removed. Removed from that tank, rinsed with DI water, and then put it into the anodizing tank. Connected the battery charger up to the cathode and anode and set it to run. After about an hour the reactions had stopped, which means all that can be done has been done. Removed, rinsed again with DI water, and set to sit in the dye bath. I checked on it at 20 minutes, not the color I wanted, back into the pool. At ~45 it still needed some more. I started the sealing water to boil (had previously gotten it up to temp, then stopped when it became clear I would need more time in the dye bath). Checked after about an hour total and it was looking really good. Added the sealing solution to the boiling water, mixed fully and then placed the now dyed lower into the pot (after rinsing the lower with more DI water). Let it boil for 20 minutes, removed, rinsed with more DI water and then set to dry overnight.

Result:

300 Blackout pistol before Saturday night:

300 Blackout pistol this morning after anodizing/dyeing last night:

Since the first picture I had also wrapped the pistol buffer tube with paracord. Just to act as padding between the metal tube and me when doing a cheek weld (easier for me than putting to my shoulder).

Technically you can dye the aluminum any color you can mix up. You can get dye from Caswell if you want, or use Rit dye from the fabric store.

I did reserve the sealing solution this time. I have a good amount of what you add to the water, but figured why not save it. I should be able to get at least a few more lowers out of the same batch. I have found that stripping anodizing off of parts fouls the NaOH solution pretty fast. But, it's easy to mix up more. If you mix it on the stronger side, put it near a fresh air source and put a loose lid over that bucket. The part will turn a dark grey when the NaOH has done it's job.

![ROFL2 [rofl2] [rofl2]](/xen/styles/default/xenforo/smilies.vb/035.gif)

![ROFL [rofl] [rofl]](/xen/styles/default/xenforo/smilies.vb/013.gif)

![This Thread Is Worthless Without Pics [pics] [pics]](/xen/styles/default/xenforo/smilies.vb/this_thread_is_worthless_without_pics.gif)

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)