I've been quiet about it so far, as it is taking WAY too long for me to put this thing together.

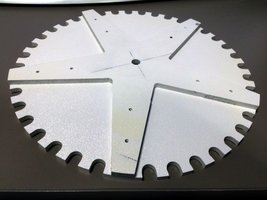

That said, I've drawn some shell plates for a DIY bucket case collator. 10.125" in diameter, as this is the required diameter of the 5 gallon pail (with 1/8" clearance) I'm using.

I started with the DXF files from EntirelyCrimson (http://entirelycrimson.com/accessories.html) for shell diameters and lengths, and borrowed their clutch clearance idea (large dia hole in shell plate, which will allow the clutch to drive the star wheel rather than the shell plate directly.)

I needed the extra height of the clutch clearance as my drive motor is close to the plate surface.

Without further ado:

- - - Updated - - -

How do I reply to myself and have it NOT appear as an edit on the previous???

- - - Updated - - -

DRfsdffsdc

- - - Updated - - -

Doggammit!

That said, I've drawn some shell plates for a DIY bucket case collator. 10.125" in diameter, as this is the required diameter of the 5 gallon pail (with 1/8" clearance) I'm using.

I started with the DXF files from EntirelyCrimson (http://entirelycrimson.com/accessories.html) for shell diameters and lengths, and borrowed their clutch clearance idea (large dia hole in shell plate, which will allow the clutch to drive the star wheel rather than the shell plate directly.)

I needed the extra height of the clutch clearance as my drive motor is close to the plate surface.

Without further ado:

- - - Updated - - -

How do I reply to myself and have it NOT appear as an edit on the previous???

- - - Updated - - -

DRfsdffsdc

- - - Updated - - -

Doggammit!

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif)