The Gizmodo article has a good summary of the purpose of the experiment:

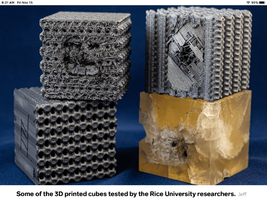

researchers 3d printed plastic cubes with complex patterns

"The technology continues to evolve, but 3D printing is still mostly used for creating prototypes or parts that won’t have to endure tremendous stresses or rigorous wear and tear. That might not always be the case, however, as researchers at

Rice University found a way to 3D print complex patterns resulting in plastic objects that are

almost as hard and durable as diamond.

The complex crisscrossing and zig-zagging patterns that are used to build up the structures of these polymer cubes are far from random; they’re strategically calculated and engineered to give these objects their incredible strength, but can be tweaked and tuned to exhibit other amazing properties as well.

The patterns are based on tubulanes, which are theoretical microscopic structures made of crosslinked

carbon nanotubes that were predicted to have remarkable properties in 1993 by chemist Ray Baughman and physicist Douglas Galvão. Tubulanes could be used to manufacture revolutionary materials that are both strong and lightweight but to date, the structures haven’t been successfully created given the challenging logistics of manufacturing with carbon nanotubes.

It turns out that the predicted properties of tubulanes aren’t limited to just objects that are manufactured with atomic-scale structures. As detailed in a

recently published paper in the

Small journal, the Rice University researchers discovered that even when those complex patterns and structures were scaled up so that they could be recreated using 3D printers, they still exhibited those predicted properties like strength and extreme compressibility, despite being rigid structures.

The researchers blasted two cubes—one made from solid polymer, and one made from a polymer printed with a tubulane structure—with a projectile traveling at 5.8 kilometers per second (which is close to 13,000 miles per hour). Neither cube was destroyed, but while the solid polymer block was left with a huge dent and cracks propagating all the way through compromising its strength, the other cube stopped the projectile by its second layer, leaving the rest of it completely intact and undamaged."