38ExtraSpecial

NES Member

Ahhh I see. I figured they all came with that option.I didn’t get any. Just the flats and the pointy ones

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Ahhh I see. I figured they all came with that option.I didn’t get any. Just the flats and the pointy ones

Makes sense. Maybe the 200 would have enough room.Wonder if it’s because of the profile.. not much diameter to play with at the tip. Round nose would have more volume to take advantage of. In the oven baking now

Can’t wait to see the resultsI sent them an email out of curiosity to see if it comes with the penta pins. Coating them up today and the first coat is done. Hope they shoot good…

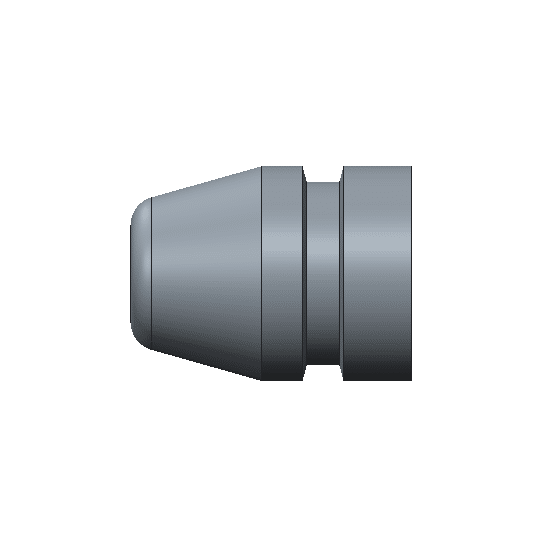

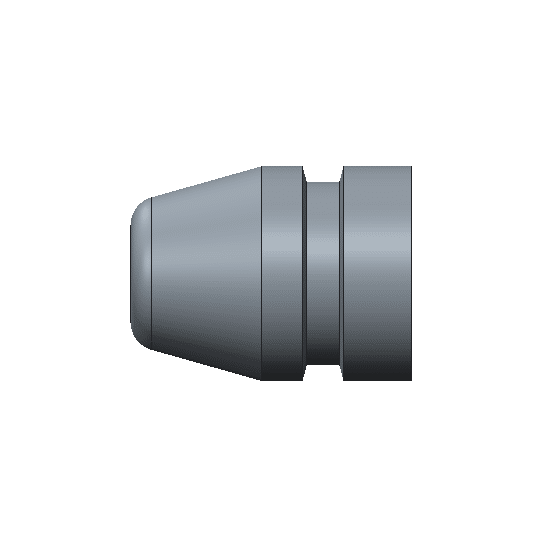

Nailed it man. They look awesome.Little on the brown side but I’m going to load em up. They averaged around 195gr.

View attachment 595006

Any real reason your going 20bhn are your pushing them hardView attachment 595029Fabulous results, awesome coating results and hardness after 4th light coating with water drop finish. Probably 20 brinell

shout out to rcbs for sending ram retaining springs within a week of emailing asking if they were available. For free even !!!View attachment 595034

A little harder than expected. I figured they were 50ww and 50pureAny real reason your going 20bhn are your pushing them hard

Nice man! That’s hard enough for whatever you need to doView attachment 595029Fabulous results, awesome coating results and hardness after 4th light coating with water drop finish. Probably 20 brinell

shout out to rcbs for sending ram retaining springs within a week of emailing asking if they were available. For free even !!!View attachment 595034

We need to get some loads into the ballistic gel man.View attachment 595029Fabulous results, awesome coating results and hardness after 4th light coating with water drop finish. Probably 20 brinell

shout out to rcbs for sending ram retaining springs within a week of emailing asking if they were available. For free even !!!View attachment 595034

I would love to do that! I have the blackout coming together with adjustable gas block and some test loads ready to go. when i get things running smooth and that 260gr mold comes in we are in for some ballistic gel slapping good times youknowhatimean!We need to get some loads into the ballistic gel man.

Oh yeah! I haven’t done much rifle gel testing. Other than some 7.62x39 and some 5.56I would love to do that! I have the blackout coming together with adjustable gas block and some test loads ready to go. when i get things running smooth and that 260gr mold comes in we are in for some ballistic gel slapping good times youknowhatimean!

Let’s make it happen! I would love to get the crew together if someone has a range that will host all of us.Is this a call for a NES casters range day?

No but interestedHas anyone tried Silhouette in a 38 Special with a 158gr coated bullet? I might load up a few for testing.

Damn that’s beautiful.Needed to try out an MP slug mold and replenish my 380 supply.

View attachment 595720

Pot cover works great - can preheat a couple of ingots and I get almost no oxidation in the melt.

The bad - hard to see the level. I have to keep an eye on the PID and refill ass soon as the temp drops (thermocouple uncovered)

View attachment 595717

Like always the MP mold is great - But it is heavy, really heavy.

Only cast a few as I'm not setup to load shells yet - maybe once supplies are more available I'll be able to get 209's and wads.

View attachment 595718

Cast up a couple of pots before I realized I grabbed the 125g 356 mold not the 102g. So now I have an extra 2k of 9mm to coat and size but still need to cast for 380.

Should have realized my mistake since the 102g only comes in 2 cavity and the 6 cavity 125 was dropping like rain.

Amazing how fast you can go through 40+ lbs of lead when your equipment is running right.

There is enough room to see the level if you look at the opening by the valve. It's just easier to look at the PID display.@pastera what if you drill a hole in the center of the cover and add a floating lead depth gauge which could be as simple as a rod attached to a disc that floats up and down. You could even mark 1/4, 1/2, 3/4 and full.

www.mp-molds.com

www.mp-molds.com

There is enough room to see the level if you look at the opening by the valve. It's just easier to look at the PID display.

The melt stays the same temp until the thermocouple is uncovered so you can run down lower than a stock pot.

At this point if I add anymore gizmos it's going to turn into an automatic casting machine.

Now I just need to convince myself I need another mold and choose which one

Or

MP 358-93 HP PB 4 cavity mold

Best moulds for casting lead bullets. Hollow point, hollow base or solid bullets. Molds are Brass or aluminum.www.mp-molds.com

Lee Precision, Inc.. Mold 6 Cav Tl356-95-rf

Lee Six Cavity Mold produces a .356 diameter 95 grain round nose bullet suitable for cartridges like 380 Auto, 9mm Luger, and 38 Super Auto..leeprecision.com

I know what the correct answer is - just need to get past the inner skinflint.

Right and order both lee is cheap enough to use while you wait for the M&P1-2 seconds….

New mold is amazing… had a bit of a drop issue with my second cavity and I hit it a few times with pencil but all and all it was great.

I read this and was wondering about this comment "I hit it a few times with a pencil." Are you saying this because the the graphite in a lead pencil will help the cavity with sticking?

if you shoot a lot of those coated bullets - how is the barrel lead build-up situation there? do you need to clean the barrel somehow once in a while, or is it efficiently not an issue for a pistol?Yes - graphite the pins on a hollow point/base mold if the bullets don't release easily