Definitely get some SR target centers, blacken those front sights!That was irons

Lookng good

I generally test loads at 50 yards.

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

Definitely get some SR target centers, blacken those front sights!That was irons

Amazing find!So I was walking a water front where ship breaking used to happen at low tide and there she was guy I was with thought I found gold. And no not giving up the location. Any one familiar with the foundry roughly 60lbs haven't scaled it yet

If I didnt have my back done a few months ago I would be there diving nowAmazing find!

Sounds like you need to find a friend that owes you a favor and doesn’t cast.If I didnt have my back done a few months ago I would be there diving now

Ahh good point. I don’t dive so I didn’t figure that in.I was more concerned with weight of gear being a beach dive tanks and weights would be the killer could float the ingots. Found a 12 lb drive weight about a mile down the coast today must be my lucky week.

I hate it when that happens.View attachment 506982

Got some time in last night to pour some more 8mm and some .312’s. Regretted not throwing in some pewter and I had a few more rejects then normal.

your gong to get wrinkles if the alloy and mold temp are not "right" , most of the "rejects" I see look more like dirty molds or a little grease/lube/oil found its way and or wrong tempsView attachment 506982

Got some time in last night to pour some more 8mm and some .312’s. Regretted not throwing in some pewter and I had a few more rejects then normal.

yup only a few I would toss back inI hate it when that happens.

The look good though.

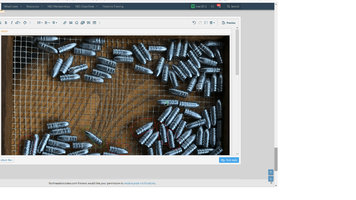

Thanks for taking the time and providing me some tips it’s greatly appreciated. I tried to keep the allow temp slightly above 700 and I’ll try to drop it down to about 650. I’ll give the molds a good scrubbing and give it another pour. I was going to ask about the ones that have that galvanized appearance and what causes it. Here is a picture of the ones I poured the other night. Oh another quick question…. I’m loading the 8mm with 17-18.5 gr of 2400, are gas checks required or will lube only do the trick? I went through about 150 8mm yesterday at the range so I have to load up more.your gong to get wrinkles if the alloy and mold temp are not "right" , most of the "rejects" I see look more like dirty molds or a little grease/lube/oil found its way and or wrong temps

Im not the best at editing. I tried to marked some bullets as follows

RED- looks more like oil contamination ?

WHITE- looks like holes or pits this can happen when alloy and mold are 2 hot, most of your bullets look frosted so the temps are already a tad high.

GREEN - you can see the frosting starting. Frosting from what I have read is from the alloy taking to long to solidify and it gets that crystalized look or galvanized look.

Clean your molds with hot dish soapy water and a tooth brush, start over and dont let your alloy run to hot. 700' works really well for me.

Depending on your alloy and bullet size. for some small bullets I have 32 cal 80 grain rn I can run as low as the alloy will flow out of the lee pour spout. which is about 630'F

lead and lead tin alloys will melt at around 620"F- ish

View attachment 507618

Your bullets look pretty good, frosting is not a big problem.Thanks for taking the time and providing me some tips it’s greatly appreciated. I tried to keep the allow temp slightly above 700 and I’ll try to drop it down to about 650. I’ll give the molds a good scrubbing and give it another pour. I was going to ask about the ones that have that galvanized appearance and what causes it. Here is a picture of the ones I poured the other night. Oh another quick question…. I’m loading the 8mm with 17-18.5 gr of 2400, are gas checks required or will lube only do the trick? I went through about 150 8mm yesterday at the range so I have to load up more.

-Jay

View attachment 507681

My first casting experience was with my dad , on the tailgate of the truck.I’m using the Lee 4-20 with a RCBS thermometer.

Looks like less wrinkles…you will getPoured a 1/2 pot of lead and kept it between 625 and 675ish. Went slow with the two molds and I went a little to cold with the molds. 3 on my hot plate was to hot and 1 was to cold. Same alloy minus the extra tin.

Nice score!Picked up some pewter at Goodwill, The Wilton Co., RWP, $4 for both. At this point, I have more pewter than lead. Got to find some lead.

View attachment 513379View attachment 513380

I stopped by a local junk shop where I have made some good deals on pewter in the past.Picked up some pewter at Goodwill, The Wilton Co., RWP, $4 for both. At this point, I have more pewter than lead. Got to find some lead.

View attachment 513379View attachment 513380

You’re an animal! Good work man!View attachment 516280

Three coats of Zombie green and they look pretty good. I wanted to try to load up some X39 but I have to check the diameter to see if they are bigger than the bore size of .313. And I have to dig around to see if I bought the Dillon conversion kit. Worse case I know these will make great 06 rounds. I could try to load up a few on a single stage I bought for sizing. It’s the cheap Lee model.

You slugged your rifle? What model was .313”View attachment 516280

Three coats of Zombie green and they look pretty good. I wanted to try to load up some X39 but I have to check the diameter to see if they are bigger than the bore size of .313. And I have to dig around to see if I bought the Dillon conversion kit. Worse case I know these will make great 06 rounds. I could try to load up a few on a single stage I bought for sizing. It’s the cheap Lee model.

The sks is east to load cast for and cycles on some fairly light loads.It’s a Chinese Type 56 and the bore is In good condition. Maybe I screwed up and my measurements are incorrect. Maybe is should slug it again.