NH Phantom

NES Member

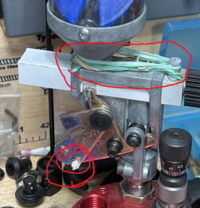

Ive been setting up my reloading room for a couple months now. I started loading some 45 acp on my dillon 750 to maks sure everything is dialed in and set up new toolheads. Brass was sticking really bad in the powder funnel. I came across a video on youtube by Modifier 472.

I cut the end of the funnel off about 3/16 of in inch with a grinder and the tube chucked in my drill press. Beveled the end. Sanded the end with 180, 320, 600, and 1200 paper. Then polished the end with some metal polish I had on hand. Took about 10 minutes total. This thing now works awesome. Check out his video if interested. Will be adding a bunch of pics of my room when finished soon.

I cut the end of the funnel off about 3/16 of in inch with a grinder and the tube chucked in my drill press. Beveled the end. Sanded the end with 180, 320, 600, and 1200 paper. Then polished the end with some metal polish I had on hand. Took about 10 minutes total. This thing now works awesome. Check out his video if interested. Will be adding a bunch of pics of my room when finished soon.