xero2099

NES Member

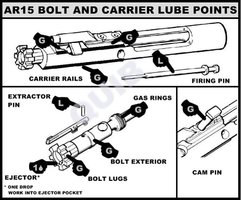

i have been having issues with my Ar since day one its was one i put together so its been a side project. it has many problems it will have failure to feed issues, wont lock back on last round, it will jam and wont go fully into battery with a magazine inserted. as far as trouble shooting I have usgi 20 rounders I have been using, they all work fine on my Brothers AR so i know its not the mags. I am using a spikes t3 heavy buffer, i have tried it in my Bros Ar as well and it works fine. I have tried his complete upper(bcg,charging handle) on my lower and everything works fine. I then tried my complete upper on his lower and the issues followed it. I completely cleaned my upper and lubed the crap out of my bcg and tried again on both lowers it still jams or wont go into battery. the last thing i tried was using the bcg form my bros Ar on my upper and everything was working fine. so it looks like there is an issue with my bcg. is there a way to trouble shoot and fix it or am i better off getting an new one?

Last edited: