Trying to get my P30SK milled for a 507K as I much prefer to carry something DA/SA than my VP9 optics ready. Anyone have experience with SAS for slide milling? Prices are extremely reasonable compared to the competition. It looks like at least on the P30, he would just get rid of the rear sight and re-dovetail it to the front of the optic if I choose to. Are backup irons really that important? Plenty of red dots have a makeshift iron notch towards the rear anyway. I figure I'll just put up a mid height front to line up with the iron-notch on the optic.

HK P30 Red Dot Cutout Service (No dovetail relocation)

This service includes the following for your HK P30sk/P30/P30L models. Slide not included, you must send in your slide for milling. *For P30sk variants always select the .40 caliber option. *9mm variants (excl P30sk) have a deep cavity that must be mitigated by an adapter plate under the optic...

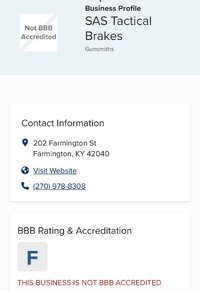

www.sastacticalcustoms.com