It looks like there hasn't been a 'what is your dream bench' thread in a few years.

What would you want in a bench setup?

I've basically convinced myself to buy a super 1050 (which might get autobotted at some point). But, I feel like I should have a place to put it.

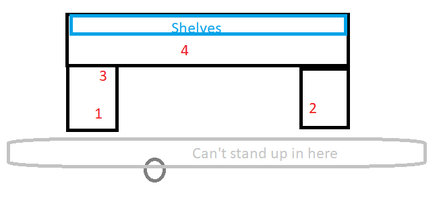

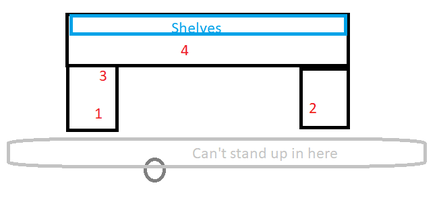

Space: Here's a diagram of the area I can set aside for it (I can get more, but then I have to move stuff, and ain't nobody got time for that). I mean, I suppose I could also just take over an unused guest room, but basement seems like the appropriate places.

And, yes, I know the diagram, viewed in 3d looks like something from Fallout - indeed, the walls aren't there in real life, they just represent the area beyond which I have other things (welder and washer/dryer in one section, cnc in another, woodworking in another, artsy bullshit in another. I couldn't figure out how to represent it, but the space has head-height problems for standing and walking (specifically, cast iron pipes at about 2 inches closer to the ground than I am, which is the precise height to catch me unawares and rattle all the pipes in the house with my skull). Two lally columns in the working area, which I suppose I could attach things to for stability. My existing gunsmithing bench has to fit in this area too

Highest height is about 7 feet, 6' in some places with the pipes or other things. How far away from the ceiling should the super 1050 (with all the bells and whistles) mount?

Bolted to cement, also to wall for stability.

What are your lessons learned since last time? What practical things should I consider?

Thanks,

JRP

What would you want in a bench setup?

I've basically convinced myself to buy a super 1050 (which might get autobotted at some point). But, I feel like I should have a place to put it.

- How thick can the benchtop be where it's going to mount?

- I got the impression that mounting it in the center is the righter thing.

- I feel like it has to be mounted lower than usual for my space (described below)

- I will be building benches, shelves, &c for this express purpose:

- Will be screwed into pressure treated drills into the concrete for stability.

- 2x4s and 4x4 posts, maybe solid core door with sacrificial mdf or the like. I am also capable of welding something 1/2" thick. Or a combination.

- I will be making it: 4x4s legs, 2x4s, probably solid core door for a top with a sacrificial mdf or the like. Or, I can mig weld something 1/2" thick or less abouts. Or a combination of the two.

- The stud wall at the stairs will get filled in with oak ply, and get shelves put on it mostly on the right-hand side. On the left, I can build maybe a bookcase-equivelent.

- how much horizontal surface area should I be thinking about, and of what kind? I've sort of had the idea of a U shape.

Space: Here's a diagram of the area I can set aside for it (I can get more, but then I have to move stuff, and ain't nobody got time for that). I mean, I suppose I could also just take over an unused guest room, but basement seems like the appropriate places.

And, yes, I know the diagram, viewed in 3d looks like something from Fallout - indeed, the walls aren't there in real life, they just represent the area beyond which I have other things (welder and washer/dryer in one section, cnc in another, woodworking in another, artsy bullshit in another. I couldn't figure out how to represent it, but the space has head-height problems for standing and walking (specifically, cast iron pipes at about 2 inches closer to the ground than I am, which is the precise height to catch me unawares and rattle all the pipes in the house with my skull). Two lally columns in the working area, which I suppose I could attach things to for stability. My existing gunsmithing bench has to fit in this area too

Highest height is about 7 feet, 6' in some places with the pipes or other things. How far away from the ceiling should the super 1050 (with all the bells and whistles) mount?

Bolted to cement, also to wall for stability.

What are your lessons learned since last time? What practical things should I consider?

Thanks,

JRP