God created Man

Colt made them equal

Kalashnikov made some more equal than others

Warning: using this method will guarantee that your receiver will deform like Russian letter Я, so when that happens, do not run to uncle Boris, crying that your hands grow from your ass and you can not make a simple thing done good. Already, I disappoint in you.

Do not worry, if the receiver will be warped, it will not affect your shooting accuracy, just buy another magazine or two. Have a shot of vodka, it will look straight, have another and you will have two receivers. Listen, you are not worthy to lick the sweat off Michael Kalashnikov’s underpants, so do not try this to impress your devochka.

I read many articles on internet about how to correctly heat treat your AK receiver. Some say that they are made by bearded ladies in Romania and so you can do it in your mother’s basement. Some say that it can only be done by professional “experts” with more degrees from MIT than my mother-in-law anal thermometer. I tell you the truth: they are both wrong! I don’t care how many diplomas you bought from my buddy Vlad. You can not take 4130 and forge it into samurai sword, hard as comrade Stalin will, supple as Natasha’s …. never mind.

4130 is not the most expensive steel with limited range for heat treatment. Having a heat treating oven and plenty of experience would go long, but then you would not be making an AK from scratch.

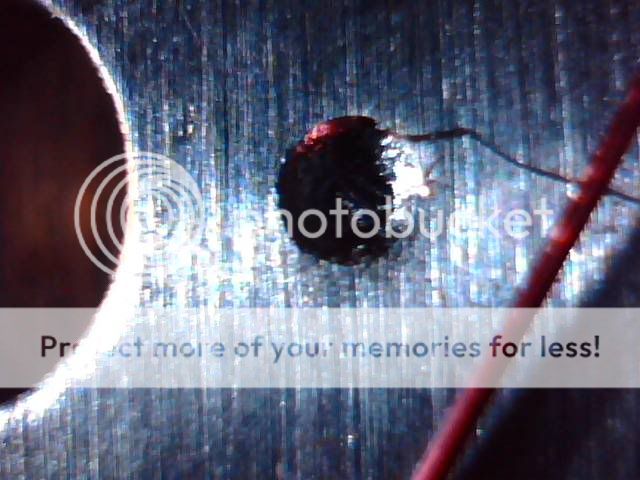

Another note. I see this picture when people heat-treat only holes instead of all receiver. What is this crap? You are too lazy? Do you also not wipe your entire buttocks after Mexican feast?

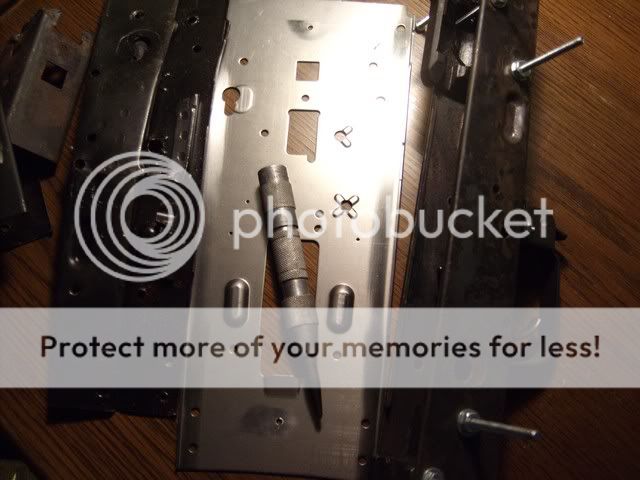

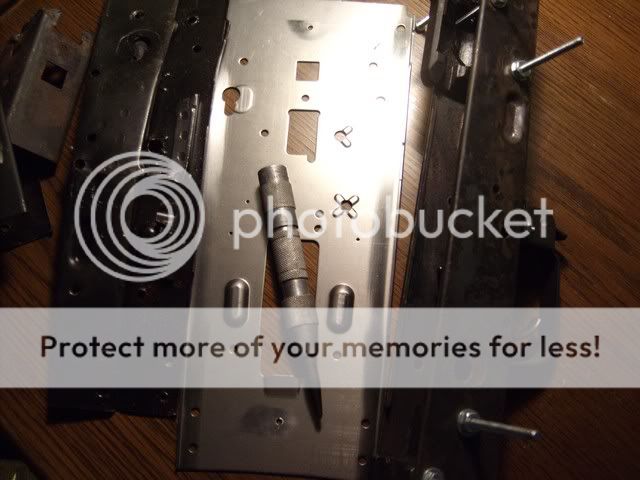

OK, let's see the receiver that I'm about to destroy:

Heat treating ovens and proper tools in general are very expensive. I had to scrounge my milsurp heap for something tubular. Any resemblance to distilling equipment is purely coincidental. Basically, you need something to contain the flame. This thingy actually has refractory lined inside, which makes it more useful.

Next I insert Chinese weed burner. They are $20 at HF, when on sale.

It is useful to practice ... a lot. Technically, you need to let your work piece soak in atmosphere controlled furnace, for a while to relieve the stresses of bending. Of course you used some s****y jig to bend it, so your receiver is already f****d. These pictures were taken in a bright sun, so you don't see the flame. It would still take out your arm hair and eyebrows. It has to be neutral at very least, but slightly reducing at best. Otherwise you'll burn out your s****y receiver, or worse, it will become so thin that it won't be able to support anything and you won't know it until the gas piston is trying to find your only brain cell in your skull.

Ok, this is a practice piece of sheet metal to get a hang of flames etc. Do it, it helps.

Heer, I prepare a quenching solution. I start with pure Baikal water ...

and then I add first secret ingridient

then second

... and now I need to drink more beer

The rest is simple, heat the receiver and quench it. Do it fast and even. Then stare in the bucket, smoking trying to figure out who is the ugly comrade who lives in the bucket.

Receiver has gained its soul!

The next step is to temper the receiver and rails. You need very least 400F. Most kitchen ovens go 450 - 500. Do that. A few hours, throw in some potatoes to celebrate later.

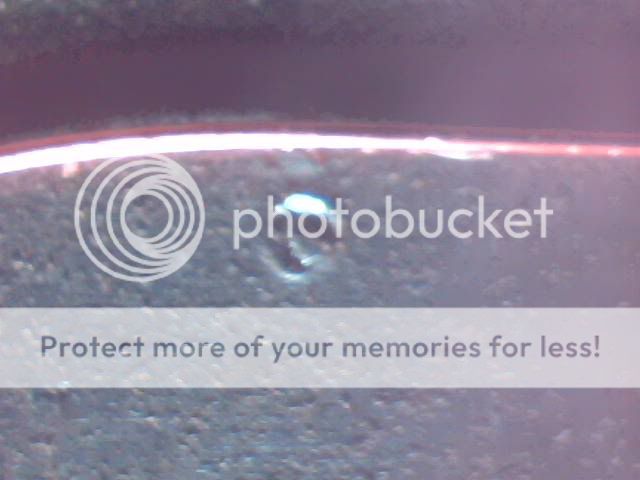

Ok, I know some comrades like science and want talk Brinell hardness but no one has the tester. Here is a quick way to check the hardness using a spring loaded center punch. Brinell, Rockwell ... f***k 'em.

I took the punch and made a single mark on my heat treated receiver, a demiled RomyG receiver, part of RomyG receiver that was quenched but not tempered etc.

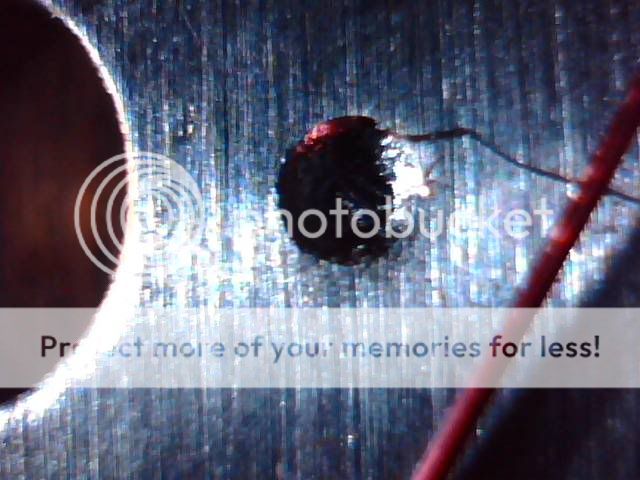

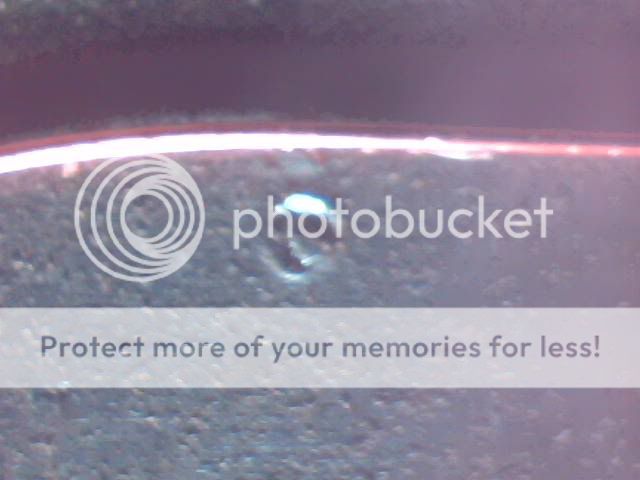

The next step requires a microscope. I read the web and people come up with crazy contraptions it is not amusing. I took one webcam and pull the guts out. Did nothing to it. It's just easier to hold it close to the piece. I also used a small part of a magnet wire to compare dimensions of the impact dimple to a constant dimension.

Here is the spare 4130 receiver flat (annealed), so if you only bend your receiver that's how soft it is:

This is a piece of RomyG receiver that was quenched to full hardness and was never annealed (it would still not shatter to million pieces like some tool steel)

This is an original RomyG receiver destroyed per ATF:

This is part of a RomyG receiver that came with the kit and that I demilled:

and finally, this is my receiver completely heat treated:

it's pretty damn close to original RomyG receivers, i.e. almost full hardness with enough tempering. I don't think that you need to go beyond 500F to temper the receiver.

Well, here is the receiver, ready to be painted

it looks bad ass just as it is

oh, yeah, here is the secret ingredients for the quenching solution:

... and Vodka? You drink it.

Colt made them equal

Kalashnikov made some more equal than others

Warning: using this method will guarantee that your receiver will deform like Russian letter Я, so when that happens, do not run to uncle Boris, crying that your hands grow from your ass and you can not make a simple thing done good. Already, I disappoint in you.

Do not worry, if the receiver will be warped, it will not affect your shooting accuracy, just buy another magazine or two. Have a shot of vodka, it will look straight, have another and you will have two receivers. Listen, you are not worthy to lick the sweat off Michael Kalashnikov’s underpants, so do not try this to impress your devochka.

I read many articles on internet about how to correctly heat treat your AK receiver. Some say that they are made by bearded ladies in Romania and so you can do it in your mother’s basement. Some say that it can only be done by professional “experts” with more degrees from MIT than my mother-in-law anal thermometer. I tell you the truth: they are both wrong! I don’t care how many diplomas you bought from my buddy Vlad. You can not take 4130 and forge it into samurai sword, hard as comrade Stalin will, supple as Natasha’s …. never mind.

4130 is not the most expensive steel with limited range for heat treatment. Having a heat treating oven and plenty of experience would go long, but then you would not be making an AK from scratch.

Another note. I see this picture when people heat-treat only holes instead of all receiver. What is this crap? You are too lazy? Do you also not wipe your entire buttocks after Mexican feast?

OK, let's see the receiver that I'm about to destroy:

Heat treating ovens and proper tools in general are very expensive. I had to scrounge my milsurp heap for something tubular. Any resemblance to distilling equipment is purely coincidental. Basically, you need something to contain the flame. This thingy actually has refractory lined inside, which makes it more useful.

Next I insert Chinese weed burner. They are $20 at HF, when on sale.

It is useful to practice ... a lot. Technically, you need to let your work piece soak in atmosphere controlled furnace, for a while to relieve the stresses of bending. Of course you used some s****y jig to bend it, so your receiver is already f****d. These pictures were taken in a bright sun, so you don't see the flame. It would still take out your arm hair and eyebrows. It has to be neutral at very least, but slightly reducing at best. Otherwise you'll burn out your s****y receiver, or worse, it will become so thin that it won't be able to support anything and you won't know it until the gas piston is trying to find your only brain cell in your skull.

Ok, this is a practice piece of sheet metal to get a hang of flames etc. Do it, it helps.

Heer, I prepare a quenching solution. I start with pure Baikal water ...

and then I add first secret ingridient

then second

... and now I need to drink more beer

The rest is simple, heat the receiver and quench it. Do it fast and even. Then stare in the bucket, smoking trying to figure out who is the ugly comrade who lives in the bucket.

Receiver has gained its soul!

The next step is to temper the receiver and rails. You need very least 400F. Most kitchen ovens go 450 - 500. Do that. A few hours, throw in some potatoes to celebrate later.

Ok, I know some comrades like science and want talk Brinell hardness but no one has the tester. Here is a quick way to check the hardness using a spring loaded center punch. Brinell, Rockwell ... f***k 'em.

I took the punch and made a single mark on my heat treated receiver, a demiled RomyG receiver, part of RomyG receiver that was quenched but not tempered etc.

The next step requires a microscope. I read the web and people come up with crazy contraptions it is not amusing. I took one webcam and pull the guts out. Did nothing to it. It's just easier to hold it close to the piece. I also used a small part of a magnet wire to compare dimensions of the impact dimple to a constant dimension.

Here is the spare 4130 receiver flat (annealed), so if you only bend your receiver that's how soft it is:

This is a piece of RomyG receiver that was quenched to full hardness and was never annealed (it would still not shatter to million pieces like some tool steel)

This is an original RomyG receiver destroyed per ATF:

This is part of a RomyG receiver that came with the kit and that I demilled:

and finally, this is my receiver completely heat treated:

it's pretty damn close to original RomyG receivers, i.e. almost full hardness with enough tempering. I don't think that you need to go beyond 500F to temper the receiver.

Well, here is the receiver, ready to be painted

it looks bad ass just as it is

oh, yeah, here is the secret ingredients for the quenching solution:

... and Vodka? You drink it.

![Thumbs Up [thumbsup] [thumbsup]](/xen/styles/default/xenforo/smilies.vb/044.gif)

![Smile [smile] [smile]](/xen/styles/default/xenforo/smilies.vb/001.gif) I had read the samauri sword effect of heat treating too. Couple of questions. Why didn't you attach the rails before heat treating? Why not using oil to quench over water? Are you going to sandblast before painting? Why food coloring in the water? Have heard to add salt and dish detergent if you use water. Also read to temper at 700 degrees.

I had read the samauri sword effect of heat treating too. Couple of questions. Why didn't you attach the rails before heat treating? Why not using oil to quench over water? Are you going to sandblast before painting? Why food coloring in the water? Have heard to add salt and dish detergent if you use water. Also read to temper at 700 degrees. ![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

![Grin [grin] [grin]](/xen/styles/default/xenforo/smilies.vb/041.gif) Urine would contain salt and therefore be good for the heat treating process.

Urine would contain salt and therefore be good for the heat treating process.![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif) What kind of UF?

What kind of UF?