Thanks whacko... I will fire one round under a towel to catch the brass and look at the primer and go from there... much obliged.I think what some are saying is being a compressed load is not the issue. Any time you shorten oal to make a projo "fit" your gun you should reduce the charge of powder and work your way up beause you are creating less space in the case (compressed or not) and this can create a higher pressure situation.. Some seem to think at 6.6 your at the high end of the charge for that powder and you just kept pushing the projo in further to make it fit without reducing the charge.

-

If you enjoy the forum please consider supporting it by signing up for a NES Membership The benefits pay for the membership many times over.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

9mm COAL ?

- Thread starter Alaskan

- Start date

pastera

NES Member

And your not listeningThanks whacko... I will fire one round under a towel to catch the brass and look at the primer and go from there... much obliged.

Start at the STARTING charge weight and work up until you hit max or see pressure signs (and then back off).

I'm working from my phone so I don't have access to the website I use that has thousands of bullet lengths

If I had that handy, I could calculate the correct seating depth (a little more complicated by the hollow base)

With that I could give you a 90% confidence but I'd still recommend starting closer to starting charge.

Thanks Pastera - I get the idea... heavier bullet taking nano-seconds longer to move into the rifling = higher pressure inside a case with less room to expand.I'm not saying it is compressed or even close to it.

The issue is that COAL is only a proxy for effective case volume.

For a shorter bullet with the same weight a shorter COAL would be used to maintain the same seating depth resulting in the same effective case volume.

Why does effective case volume matter?

Because powder burn rate is extremely effected by pressure (higher pressure = faster burn). This positive feedback is mitigated by bullet travel but if there isn't enough room in the case to limit pressure rise before the bullet inertia can be overcome then pressure can spike all the way to a kaboom.

If I was rude earlier, sorry but your response sounded like you were only looking for someone to confirm your loading and not for negative responses saying it didn't seem safe.

seems reasonable - this is why I went with 6.6 and (not 6.8 gr.) and the (4 gr. cut 121 gr. from the 125 gr. manual) and lead soft Berry's material...

I will capture one round under a towel and eval the primer and other case evidence before accepting this load as safe... and in the future start at starting loads with new untested bullets.

much obliged -

I've used Berrys Hollow base and solid base with zero issues. The 1.160 COAL is a compromise of advice on going as long as the gun liked and a " scientific" this is an average of commercial loaded ammo lengths with similar nose profiles.I'm using a Taurus 92 for test bed on this load and seein 6.8 gr. HS-6 as a maximum and Berry's is softer than XTP... no?

pastera

NES Member

Better to make a few ladder loads from the starting charge (3-5 each every 0.1gn)Thanks Pastera - I get the idea... heavier bullet taking nano-seconds longer to move into the rifling = higher pressure inside a case with less room to expand.

seems reasonable - this is why I went with 6.6 and (not 6.8 gr.) and the (4 gr. cut 121 gr. from the 125 gr. manual) and lead soft Berry's material...

I will capture one round under a towel and eval the primer and other case evidence before accepting this load as safe... and in the future start at starting loads with new untested bullets.

much obliged -

Fire all of one weight and inspect before moving to the next charge weight

I have two 9mms and both show this bullet Berrys 121 HPHB from Midway stick out beyond the hood to the same value - my first reaction is this bullet is touching the rifling - confirmed when shortening the COAL the case moved in incrementally to its proper position without touching the rifling.I prefer to stop when the plunk and spin, but yours works too

You can run an ass ton of HS6 and not get primer issues.

Do other bullet profiles load to reasonable lengths? Or does your barrel have a short leade?

The berry does have a short OAL compared to FMJ, so that could be the difference. But I would start at a lower powder charge and work up.

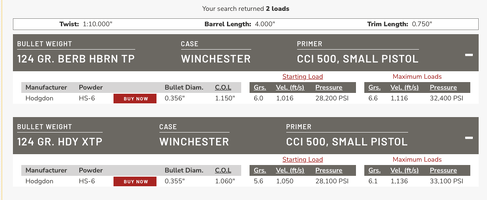

Data from Hodgdon's site. No 121gr bullets listed, but this is for the nearest weight. Starting loads are likely almost a full grain LOWER than you are proposing, especially as you are estimating case volume, not working from known load data. I think most others here are simply advising caution. Your load may end up being safe, but it is never "OK" to assume that. You do you - hope it goes well.

pastera

NES Member

Fat nosed bullets smack the lands early but are also shorter for weight so can have a shorter COAL for same seating depth.I have two 9mms and both show this bullet Berrys 121 HPHB from Midway stick out beyond the hood to the same value - my first reaction is this bullet is touching the rifling - confirmed when shortening the COAL the case moved in incrementally to its proper position without touching the rifling.

Problem is that without length measurements for the bullets it's hard to know the correct COAL for the shorter bullet

I got these Berry' HPHB to try 121 gr. in 9mm at .13 cents each... the three reviews didn't reveal much - intent now on SQEAKY cleaning my seater die and adjusting everything to give me a minimum rifling clearence - .003" and eliminate the crimping portion of the seating die as this is range brass and appears different thicknesses of case material and manufacturers is producing a +/- 0.010 COAL range... and yes my taper crimp die is the last step.id be looking for another bullet company.............but judging from your avatar, youre not in this commie state.........

View attachment 719917

Go Arizona Chiefs!

Last edited:

Precision Delta is offering 124 gr JHP bullets at just over 11¢ (as an example), and their 124 gr FMJs are about 10¢, all with free shipping. Again, just an example, but you can get better bullets for less... I know you already have the 121 Berry's and are looking to make those work as you already have a stock of them.I got these Berry' HPHB to try 121 gr. in 9mm at .13 cents each... the three reviews didn't reveal much - intent now on SQEAKY cleaning my seater die and adjusting everything to give me a minimum rifling clearence - .003" and eliminate the crimping portion of the seating die as this is range brass and appears different thicknesses of case mount is producing a +/- 0.010 COAL range... and yes my taper crimp die is the last step.

Thanks - I'll keep those in my reload book - much appreciated information.Precision Delta is offering 124 gr JHP bullets at just over 11¢ (as an example), and their 124 gr FMJs are about 10¢, all with free shipping. Again, just an example, but you can get better bullets for less... I know you already have the 121 Berry's and are looking to make those work as you already have a stock of them.

Thanks Pastera - I get the idea... heavier bullet taking nano-seconds longer to move into the rifling = higher pressure inside a case with less room to expand.

seems reasonable - this is why I went with 6.6 and (not 6.8 gr.) and the (4 gr. cut 121 gr. from the 125 gr. manual) and lead soft Berry's material...

I will capture one round under a towel and eval the primer and other case evidence before accepting this load as safe... and in the future start at starting loads with new untested bullets.

much obliged -

Hornady 10th Edition Handbook of Cartridge Reloading by Hornady Manufacturing.pdf - PDFCOFFEE.COM

© 2016 | First printingHORNADY MANUFACTURING COMPANY GRAND ISLAND, NEBRASKA 68802 U.S.A.Reloading data presented h...

just get it and do not guess.

it has to be the 11th edition also somewhere, but, i cannot find it. 10th is also just fine.

peterk123

NES Member

I did not read the whole thread so I apologize if what I am about to share is useless.

I load powder coated 124 grain round nose bullets. I own five different 9mm handguns. One of them has a match barrel and it is picky. I have to load at 1.09 overall length.

I load with be86, but i don't go near max load. I have not chronoed it but I get good results and a clean burn. I have loaded at least 25k rounds of it. All of my guns use this round.

I load powder coated 124 grain round nose bullets. I own five different 9mm handguns. One of them has a match barrel and it is picky. I have to load at 1.09 overall length.

I load with be86, but i don't go near max load. I have not chronoed it but I get good results and a clean burn. I have loaded at least 25k rounds of it. All of my guns use this round.

Got my SA-35 to the range and loving it - wife made me wait for it till my BD and I've put every powder primer and bullet combination through it with excellent results.I'm not saying it is compressed or even close to it.

The issue is that COAL is only a proxy for effective case volume.

For a shorter bullet with the same weight a shorter COAL would be used to maintain the same seating depth resulting in the same effective case volume.

Why does effective case volume matter?

Because powder burn rate is extremely effected by pressure (higher pressure = faster burn). This positive feedback is mitigated by bullet travel but if there isn't enough room in the case to limit pressure rise before the bullet inertia can be overcome then pressure can spike all the way to a kaboom.

If I was rude earlier, sorry but your response sounded like you were only looking for someone to confirm your loading and not for negative responses saying it didn't seem safe.

COAL is ~ 1.080" and the Berry's HPHB are excellent - thanks for the information and my latest question on what is different when an identical projectile leaves the muzzle of a 4.5" barrel at the same velocity using different propellants is waiting.

pastera

NES Member

Every powder has a different flame propagation profile, and that profile changes dramatically with pressure, along with different densities and energy content.Got my SA-35 to the range and loving it - wife made me wait for it till my BD and I've put every powder primer and bullet combination through it with excellent results.

COAL is ~ 1.080" and the Berry's HPHB are excellent - thanks for the information and my latest question on what is different when an identical projectile leaves the muzzle of a 4.5" barrel at the same velocity using different propellants is waiting.

All of those characteristics work together to create a pressure pulse that maximizes the area under the curve to get the best velocity per grain of powder while staying within safe pressure limits across temperature and chamber variations.

So if you want the same velocity out of a different powder then you need to select the right charge weight for that new powder that achieves the same area under the pressure curve - AND verify that the powder is stable for that load. Some powders simply will not safely replicate a different powder's achieved performance.

No argument; but the question remains... if a safe charge of different powder brands used to creat an identical projectile to leave the muzzle from the same firearm barrel) will the accuracy then be within that same group if variations of velocity are eliminated?Every powder has a different flame propagation profile, and that profile changes dramatically with pressure, along with different densities and energy content.

All of those characteristics work together to create a pressure pulse that maximizes the area under the curve to get the best velocity per grain of powder while staying within safe pressure limits across temperature and chamber variations.

So if you want the same velocity out of a different powder then you need to select the right charge weight for that new powder that achieves the same area under the pressure curve - AND verify that the powder is stable for that load. Some powders simply will not safely replicate a different powder's achieved performance.

Q? are 'identical velocities' from the same firearm using identical projectiles... regardless of primer powder brass going to give near identical results?

Is there anything else internal of or related to powder brand burn rates etc that would interfere with this presumption?

Last edited:

pastera

NES Member

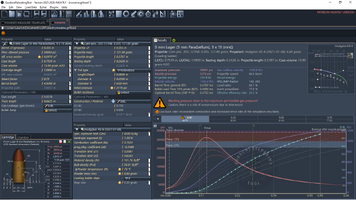

Tossed some of the original info into Gordon's Reloading Tool - I don't have exact data for the berry's bullet so used something close and SWAG'd the hollow base

6.6gn of HS-6 is very close to over pressure on standard 9mm - yes most modern guns can handle +P but you want to know that you are testing those waters.

6.6gn of HS-6 is very close to over pressure on standard 9mm - yes most modern guns can handle +P but you want to know that you are testing those waters.

Attachments

pastera

NES Member

For handguns, similar burn rate powders achieving similar velocities in middle of their capabilities are going to perform pretty much the same at the short distances involved.No argument; but the question remains... if a safe charge of different powder brands used to creat an identical projectile to leave the muzzle from the same firearm barrel) will the accuracy then be within that same group if variations of velocity are eliminated?

Q? are 'identical velocities' from the same firearm using identical projectiles... regardless of primer powder brass going to give near identical results?

Is there anything else internal of or related to powder brand burn rates etc that would interfere with this presumption?

Even with identical velocities, there will be some variation in recoil impulse between powders will large differences in burn rate so that will affect point of impact also

- Joined

- Apr 24, 2005

- Messages

- 47,526

- Likes

- 33,542

HS-6 is the same as the discontinued WW540. This is a decent powder if you are pushing high velocity loads - like in a 38 super[comp], or driving 9mm to major power factor levels, but may not be the best for typical 9mm loads.

M60

NES Member

Lol. I bulged a cylinder on a Smith 629 playing with Keith loads. Kept adding 1/10 of a grain to see how far I could go. Gun came back from Smith with a new cylinder and a note that said " don't do that any more".The 6.6 gr. Of HS-6 is not a compressed load for this projectile or any standard 121 - 125 gr. bullet - might be for a Barnes - I started at 1.125 " and found the plunk test sticking out far in excess of a factory cartridge and shortened the depth to match factory minus a few thousandth.

For sure - compressed loads are never going into my guns - I've been loading for 50 years and while I don't know everything I've never kaboomed anything - flattened a few primers with some Elmer Keith loads which were scratched from my Favorites.

When Shooting Metallic Silhouette I shot a 4" Model 29 'rickety' with an old Sierra book recipe of 23.3 gr of 2400 under Sierra 240s with good results then years later bought a replacement - that maximum has since been lowered but it was a hum-dinger on chickens and pigs - Turkeys and Rams went down with authority.Lol. I bulged a cylinder on a Smith 629 playing with Keith loads. Kept adding 1/10 of a grain to see how far I could go. Gun came back from Smith with a new cylinder and a note that said " don't do that any more".

Share:

Similar threads

- Replies

- 49

- Views

- 1K