Hi everyone,

New to reloading 12ga slugs. VERY NEW. I've got some lead, I've got the mold, I've got the hulls. Soon I will have some slugs.

When I do I need to buy 209 primers and WADS.

Wads is where I get hung up. The Lee mold manual suggests I can use shot cups or wads but all the listed data in the manual as you would suspect does not correspond to readily available product.

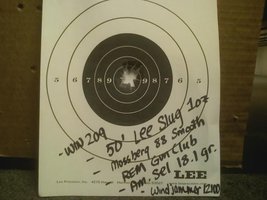

I can get WINDJAMMER 1oz Wads - or shot cups with the little plastic "petals". Now I understand the height of the slug has to be determined by the powder depth at proper charge and wad...but before I even get there:

Does anyone know if you can use "any" type of 1oz wads / shot cups? Or is there a specific type of wad that HAS TO BE USED with a slug?

Aside from discouraging warnings (as I am trying to do it right) any wisdom you could impart from your experience that would be helpful is appreciated.

Thanks everyone!

New to reloading 12ga slugs. VERY NEW. I've got some lead, I've got the mold, I've got the hulls. Soon I will have some slugs.

When I do I need to buy 209 primers and WADS.

Wads is where I get hung up. The Lee mold manual suggests I can use shot cups or wads but all the listed data in the manual as you would suspect does not correspond to readily available product.

I can get WINDJAMMER 1oz Wads - or shot cups with the little plastic "petals". Now I understand the height of the slug has to be determined by the powder depth at proper charge and wad...but before I even get there:

Does anyone know if you can use "any" type of 1oz wads / shot cups? Or is there a specific type of wad that HAS TO BE USED with a slug?

Aside from discouraging warnings (as I am trying to do it right) any wisdom you could impart from your experience that would be helpful is appreciated.

Thanks everyone!

![Wink [wink] [wink]](/xen/styles/default/xenforo/smilies.vb/002.gif)

![Thinking [thinking] [thinking]](/xen/styles/default/xenforo/smilies.vb/010.gif)