I have an old Century Arms Bearcat single shot .22 rifle, circa 1931 I think. It's a cheapo gun, but has been handed down through the family and has some sentimental value to me. This was the first gun that I owned, passed on to me by my dad on my 10th birthday, and very well used over the years. I've probably put at least 10,000 rounds through it.

It's been in storage for the last 10 years or so needing some work, and I recently got it out and started to look at trying to get it shootable again and ready to hand on to my son.

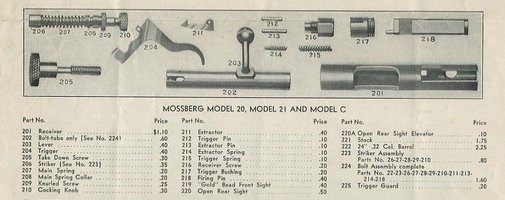

I believe this was actually built by Mossberg, as the bolt/action appears to be identical to the Mossberg Models 20, 21, and C that were made in 1931-1932 (see below). The only difference between the 2 guns that I can see is a slight difference in the shape of the stock, so I believe parts for those Mossberg models would be interchangeable.

The top end of the trigger that catches in the bolt is worn down so far that bumping the stock will set it off.

The firing pin is broken and extractor is worn down to the point that it no longer catches the rim of the cartridge.

If I could find a complete bolt assembly (or the needed components thereof) and a trigger I'd be all set, but I've not been able to find anyone who still has parts for these old guns laying around (even used). Any help sourcing these parts would be very much appreciated!

Thanks!

Jake

It's been in storage for the last 10 years or so needing some work, and I recently got it out and started to look at trying to get it shootable again and ready to hand on to my son.

I believe this was actually built by Mossberg, as the bolt/action appears to be identical to the Mossberg Models 20, 21, and C that were made in 1931-1932 (see below). The only difference between the 2 guns that I can see is a slight difference in the shape of the stock, so I believe parts for those Mossberg models would be interchangeable.

The top end of the trigger that catches in the bolt is worn down so far that bumping the stock will set it off.

The firing pin is broken and extractor is worn down to the point that it no longer catches the rim of the cartridge.

If I could find a complete bolt assembly (or the needed components thereof) and a trigger I'd be all set, but I've not been able to find anyone who still has parts for these old guns laying around (even used). Any help sourcing these parts would be very much appreciated!

Thanks!

Jake

![Laugh [laugh] [laugh]](/xen/styles/default/xenforo/smilies.vb/012.gif)